Applications of Pipe Insulation Brackets in Green Energy Projects

Author:Mingde Time:2025-10-23 13:59:57 Click:193

The New Era of Smart Pipe Support Systems

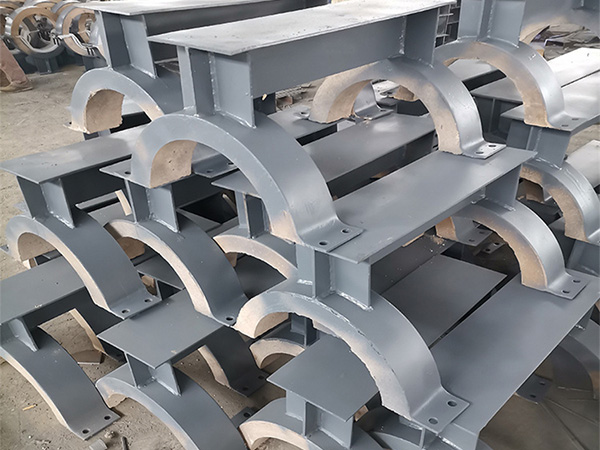

As the global energy sector accelerates toward sustainability, the demand for durable and efficient Pipe Insulation Brackets has never been greater. These specialized supports form the invisible backbone of modern renewable energy infrastructure, ensuring pipelines remain stable, well-insulated, and energy-efficient across a variety of applications—from geothermal heating to solar thermal plants.

With continuous advancements in materials science and manufacturing, China manufacturers now play a pivotal role in supplying bulk quantities of precision-engineered insulation brackets that meet international green standards while offering cost-effective scalability.

1. Why Pipe Insulation Brackets Are Critical in Green Energy Systems

A Pipe Insulation Bracket is more than just a support component—it’s an essential element in maintaining system integrity and efficiency. Its role includes stabilizing pipelines, minimizing vibration, and ensuring insulation continuity to reduce energy loss.

When integrated properly, these brackets:

·Prevent thermal bridging, conserving heat and lowering operational costs.

·Maintain mechanical balance in fluctuating flow or pressure conditions.

·Protect against condensation and corrosion that often damage insulation layers.

·Extend service lifespan for entire pipeline systems.

This makes them indispensable for industries transitioning toward clean and efficient energy distribution.

2. Key Applications Across Green Energy Sectors

The adaptability of Pipe Insulation Brackets allows them to support diverse energy projects where temperature control and durability are crucial.

a. Geothermal Power Generation

In geothermal plants, high-temperature fluids flow through long underground and surface pipelines. Insulated brackets maintain consistent thermal performance and structural alignment under fluctuating loads.

b. Solar Thermal Systems

Solar power plants rely on heat transfer fluids traveling through insulated pipes. Well-designed brackets prevent heat dissipation and mechanical stress caused by expansion and contraction cycles.

c. Biomass Processing Facilities

Pipelines carrying bio-oils, gases, or steam require thermal stability to maintain reaction efficiency. Proper insulation brackets ensure controlled flow and temperature management.

d. District Heating and Cooling Networks

In urban energy distribution systems, thousands of insulated pipelines depend on bracket integrity to prevent sagging, thermal cracks, or insulation fatigue.

Through large-scale bulk supply, China manufacturers provide project-ready solutions for each of these green energy scenarios—customized, tested, and optimized for reliability.

3. Design and Engineering Considerations

Engineering an effective Pipe Insulation Bracket requires balancing thermal, mechanical, and environmental factors. Every design choice influences the overall performance of the pipeline network.

a. Material Selection

High-performance composites, such as glass fiber, polyurethane foam, and phenolic resin, are replacing conventional steel to minimize thermal conductivity while retaining load strength.

b. Thermal Isolation and Load Management

Finite Element Analysis (FEA) is often used to model load distribution and heat flow. This ensures the bracket maintains mechanical strength without compromising insulation integrity.

c. Durability and Corrosion Protection

Anti-corrosive coatings and polymeric shells protect against moisture and environmental stress, particularly in outdoor or coastal installations.

Modern China manufacturers leverage simulation, testing, and quality certification to ensure each Pipe Insulation Bracket meets ISO, EN, or ASME standards before export.

4. Precision Manufacturing: China’s Competitive Edge

Automation and digitalization have redefined how insulation brackets are produced. Leading China factories now integrate:

·CNC machining for precision component shaping.

·Automated molding to guarantee consistent insulation density.

·Laser quality scanning for dimension verification in mass production.

·Robotic assembly lines that ensure speed and repeatability for bulk orders.

This combination of technology and scale enables China manufacturers to deliver competitive prices while maintaining global quality expectations—a defining advantage in the clean energy supply chain.

5. Environmental and Economic Impact

Using high-efficiency Pipe Insulation Brackets has both environmental and financial benefits. Proper insulation minimizes heat loss, directly reducing fuel or electricity consumption in energy transport systems.

Moreover, recyclable materials and low-carbon manufacturing techniques adopted by China suppliers align with global sustainability goals. The lifecycle benefits—lower maintenance, extended service, and improved safety—add measurable long-term value to renewable energy investments.

6. Future Trends: Smart and Adaptive Support Systems

The next stage in insulation bracket innovation lies in intelligent monitoring and adaptive design. Researchers and manufacturers are developing:

·IoT-integrated supports for real-time temperature and stress monitoring.

·AI-assisted bracket design, optimizing geometry for dynamic loads.

·Hybrid insulation materials combining strength and low conductivity.

·Eco-friendly composites with recyclability and low carbon footprints.

Such technologies will make Pipe Insulation Brackets even more integral to efficient, connected, and sustainable energy networks.

Conclusion: Reliable Pipe Insulation Brackets for a Sustainable Future

From geothermal pipelines to solar heat networks, the Pipe Insulation Bracket stands as a small but crucial part of the clean energy revolution. By ensuring stability, insulation continuity, and long-term efficiency, it enables renewable systems to operate at peak performance.

With China manufacturers leading the way in automation, material innovation, and bulk-supply reliability, global energy projects now have access to cost-effective, high-precision, and eco-conscious solutions.

In an era where sustainability drives every engineering decision, the evolution of the Pipe Insulation Bracket reflects the progress of the entire green energy movement—where innovation meets environmental responsibility.

References

GB/T 7714:Keçebaş A, Alkan M A, Bayhan M. Thermo-economic analysis of pipe insulation for district heating piping systems[J]. Applied Thermal Engineering, 2011, 31(17-18): 3929-3937.

MLA:Keçebaş, Ali, Mehmet Ali Alkan, and Mustafa Bayhan. "Thermo-economic analysis of pipe insulation for district heating piping systems." Applied Thermal Engineering 31.17-18 (2011): 3929-3937.

APA:Keçebaş, A., Alkan, M. A., & Bayhan, M. (2011). Thermo-economic analysis of pipe insulation for district heating piping systems. Applied Thermal Engineering, 31(17-18), 3929-3937.

Hot Products

Hot Products

Contact Us

Contact Us

Contact:

Mobile:+86 +86 19133378808

Website:mingdepipe.com

Address: