Collaborative Design of Pipe Insulation Brackets and Pipe Rack Structures

Author:Mingde Time:2025-10-20 14:50:06 Click:164

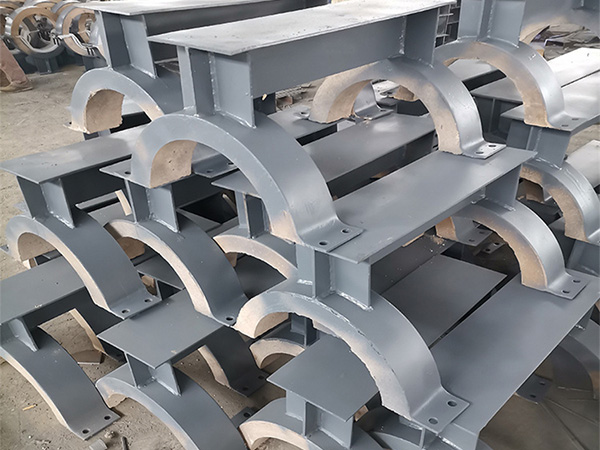

In today’s industrial construction, where safety, thermal stability, and efficiency are essential, the connection between Pipe Insulation Brackets and pipe rack structures has become a core design consideration.

Unlike older systems where brackets and racks were designed separately, modern engineering focuses on collaborative development—a process that harmonizes structure, material, and insulation performance from the start.

Supported by China manufacturers with advanced fabrication facilities and bulk production capability, these integrated solutions now set new standards for durability, modularity, and thermal protection across global infrastructure projects.

1. Why Collaborative Design Matters

For decades, pipe support and insulation systems were engineered independently. The result often included misalignment, inconsistent loads, and reduced insulation performance.

Collaborative design eliminates these conflicts by aligning the Pipe Insulation Bracket and rack system within one cohesive digital model.

This combined design approach ensures:

·Uniform stress distribution across supports.

·Continuous thermal insulation without gaps.

·Better vibration resistance and mechanical balance.

·Simplified on-site installation and maintenance.

By addressing these aspects simultaneously, project engineers achieve both structural reliability and energy efficiency—two critical goals for modern plants.

2. Integration Through Digital Design and Simulation

Digital tools such as Finite Element Analysis (FEA), 3D modeling, and Building Information Modeling (BIM) have revolutionized how support systems are conceptualized and optimized.

By simulating load behavior, thermal expansion, and vibration dynamics, engineers can test different Pipe Insulation Bracket geometries before production begins.

This digital collaboration between mechanical and structural teams allows precise optimization of both bracket strength and insulation continuity.

Advanced China suppliers are already using simulation-driven manufacturing lines that merge design verification with automated fabrication—ensuring consistency from model to material.

3. Material Collaboration Between Brackets and Racks

The synergy between insulation brackets and rack frames largely depends on material selection.

Each component must complement the other to balance mechanical strength with thermal protection.

Modern Pipe Support Systems use combinations such as:

·Aluminum and composite hybrids for lightweight efficiency.

·Stainless steel with polymer cores to minimize corrosion.

·Carbon steel frames with insulated interfaces to reduce heat loss.

·Reinforced fiberglass brackets for cryogenic or offshore applications.

Such hybrid designs preserve insulation performance while reducing overall system weight—an advantage crucial for large-scale facilities and energy-intensive plants.

4. Manufacturing Evolution and China’s Role in Bulk Production

Manufacturing innovation has redefined how Pipe Insulation Brackets are produced.

In China, state-of-the-art factories combine CNC machining, robotic welding, and automated coating systems to deliver consistent, high-quality support components at scale.

Features of this modern production system include:

·Modular, interchangeable components for flexible installation.

·Uniform quality control across large production batches.

·Surface coatings that enhance corrosion and fire resistance.

·Quick customization for project-specific needs.

With these capabilities, China manufacturers are now recognized as global leaders in bulk supply of engineered Pipe Support Systems, meeting international standards such as ISO, DIN, and ASME.

5. Engineering Coordination for Thermal and Structural Efficiency

The combined behavior of pipe racks and insulation brackets directly affects system reliability.

Collaborative engineering focuses on eliminating “thermal bridges” — zones where heat escapes due to poor insulation contact.

To address this, designers integrate:

·Insulated connection points and adjustable clamp systems.

·Expansion-tolerant joints for temperature fluctuations.

·Anti-vibration pads to reduce noise and fatigue stress.

·Modular insulation segments compatible with varied pipe diameters.

These refinements enhance both thermal protection and mechanical stability—ensuring safe, long-term operation under fluctuating environmental conditions.

6. Industrial Applications and Benefits

The benefits of jointly designed Pipe Insulation Bracket and rack systems are evident across multiple industries:

·Power generation: Supports for high-temperature steam lines.

·Petrochemical and LNG facilities: Resistant to corrosion and vibration.

·District heating and cooling: Ensures heat retention and efficiency.

·Marine and offshore systems: Withstands moisture, salt, and dynamic loads.

·Industrial manufacturing: Provides precise alignment and long-term strength.

Each project benefits from the integration of digital design, smart materials, and reliable China supplier manufacturing support.

7. Toward Smart and Sustainable Development

The next phase of Pipe Support System innovation involves intelligent monitoring and sustainable production.

Manufacturers are adopting smart sensors, recyclable materials, and AI-driven optimization tools to improve efficiency.

Emerging trends include:

·Real-time load and temperature sensors embedded in supports.

·Eco-friendly composite materials with high recyclability.

·Predictive maintenance using digital twins.

·AI-based simulation for automated stress optimization.

China’s production ecosystem is leading this transformation—offering bulk manufacturing capacity aligned with sustainability and Industry 4.0 standards.

Conclusion

The collaborative design of Pipe Insulation Brackets and pipe rack structures marks a new era in industrial pipeline engineering.

By merging mechanical stability, insulation efficiency, and digital precision, these systems redefine how industrial facilities are built and maintained.

Choosing a China manufacturer capable of bulk production ensures access to high-quality, customizable, and globally compliant components—vital for long-term reliability and energy performance.

As industries pursue greener, smarter, and more efficient infrastructure, the integrated evolution of Pipe Support Systems will continue to shape the backbone of modern industrial engineering.

References

GB/T 7714:Porzuczek J. Comparative study on selected insulating materials for industrial piping[J]. Materials, 2024, 17(7): 1601.

MLA:Porzuczek, Jan. "Comparative study on selected insulating materials for industrial piping." Materials 17.7 (2024): 1601.

APA:Porzuczek, J. (2024). Comparative study on selected insulating materials for industrial piping. Materials, 17(7), 1601.

Hot Products

Hot Products

Contact Us

Contact Us

Contact:

Mobile:+86 +86 19133378808

Website:mingdepipe.com

Address: