Design Innovations in Lightweight Insulated Pipe Supports

Author:Mingde Time:2026-01-01 23:09:20 Click:83

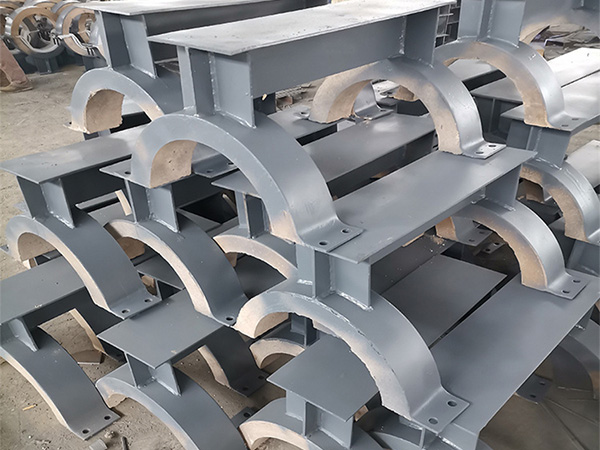

In industrial applications, the importance of pipe support systems cannot be overstated. These components are essential for ensuring that pipelines remain securely anchored and supported, minimizing the risks of vibration, thermal expansion, and mechanical stress. However, the traditional designs for pipe supports have often been heavy and cumbersome, which can add to the overall weight and complexity of the system. In response to these challenges, the development of lightweight insulated pipe supports has emerged as a game-changer. This article delves into the latest design innovations in these systems, highlighting how manufacturers are reshaping pipeline insulation brackets to enhance performance, reduce costs, and improve overall efficiency.

Understanding Lightweight Insulated Pipe Supports

A pipe support system typically comprises various components such as brackets, hangers, and insulation materials designed to stabilize and protect pipes. Insulated pipe supports, specifically, are engineered to prevent heat loss, manage temperature fluctuations, and minimize energy consumption. Traditionally, these components were designed with rigid materials and bulky frameworks that increased both weight and cost.

However, as industries demand more sustainable and cost-effective solutions, manufacturers have turned to new materials and innovative designs. Lightweight insulated pipe supports not only reduce the overall weight of the system but also offer improved thermal insulation properties, making them ideal for high-efficiency applications in industries like oil and gas, power generation, and chemical manufacturing.

Key Design Innovations in Lightweight Insulated Pipe Supports

1. Use of Advanced Composite Materials

One of the major innovations in lightweight pipe supports is the use of advanced composite materials. These materials, which combine fibers and resins, provide a unique combination of strength, durability, and lightweight characteristics. Composites are now being used in the production of insulation brackets, reducing the need for heavy steel or other metals traditionally used in support systems.

The use of composite materials also improves the corrosion resistance of pipe supports, making them suitable for environments where traditional metal supports might fail due to exposure to chemicals or harsh weather conditions . Additionally, these materials are often more cost-effective and environmentally friendly than their metal counterparts.

2. Optimized Structural Design

Another important innovation in lightweight insulated pipe supports is the optimized structural design. Engineers now use advanced computer-aided design (CAD) tools to create support systems that maximize strength while minimizing material usage. This design approach allows for pipeline insulation brackets that are both lighter and stronger, ensuring that they provide the necessary support without adding unnecessary weight.

In addition to optimizing material usage, these designs also take into account factors such as load-bearing capacity, temperature fluctuations, and potential mechanical stresses. This results in a more efficient and effective support system that meets the specific requirements of each pipeline installation.

3. Improved Thermal Insulation Properties

Thermal insulation is critical for maintaining the temperature of pipelines and reducing energy losses. In response to this need, manufacturers have developed insulation materials that not only offer better thermal performance but also help in achieving a lightweight insulated pipe support solution.

The latest insulation materials used in these systems include aerogels, which are extremely lightweight and have superior thermal insulating properties. Aerogels are now being incorporated into pipe support designs, offering significant reductions in weight while maintaining or even improving insulation performance. This innovation helps reduce energy costs and minimizes the environmental impact of energy-intensive industries.

4. Modular and Flexible Designs

Modern pipe support systems are increasingly modular and flexible, allowing for easy adjustments and customization based on specific project needs. The introduction of modular designs allows manufacturers to provide tailored solutions for clients, ensuring that each pipe support system meets the unique demands of the project.

This flexibility is especially beneficial in industries that require frequent changes or expansions to their pipeline systems. Modular components make it easier to adapt the system as the project evolves, providing a more scalable and cost-efficient solution for long-term maintenance and upgrades.

The Benefits of Lightweight Insulated Pipe Supports

1. Cost Efficiency

The use of lightweight materials and optimized designs significantly reduces the cost of production for pipe supports. By cutting down on material waste and transportation costs, manufacturers can provide more affordable solutions without compromising on quality or performance. Additionally, the reduced weight of these supports leads to lower installation and maintenance costs.

2. Enhanced Durability

Lightweight insulated pipe supports are not only cost-effective but also durable. The advanced materials used in their construction, such as high-strength composites and corrosion-resistant alloys, ensure that these supports can withstand the rigors of industrial environments. This durability is crucial for maintaining the integrity of pipeline systems over time and preventing the need for costly repairs or replacements.

3. Environmental Sustainability

The shift toward lightweight, composite materials in pipe support systems also contributes to environmental sustainability. The reduced weight of these systems lowers the carbon footprint associated with transportation and installation. Additionally, the use of materials with superior thermal insulation properties helps reduce energy consumption, making these systems more energy-efficient and environmentally friendly.

4. Improved Safety and Performance

Lightweight insulated pipe supports also improve the safety and overall performance of pipeline systems. The optimized design ensures that the supports are capable of withstanding the stresses and strains associated with fluctuating temperatures, vibrations, and mechanical loads. This results in a safer operating environment, particularly in high-risk industries such as oil and gas, where pipeline integrity is crucial.

Choosing the Right Manufacturer and Supplier

When selecting pipeline insulation brackets and supports, it is essential to choose a manufacturer with a proven track record of producing high-quality, lightweight solutions. A reliable supplier should be able to offer products that meet industry standards and certifications, ensuring that the supports are not only cost-effective but also safe and durable for long-term use.

Look for a supplier that can provide bulk production options, especially if you are involved in a large-scale project. A manufacturer with experience in producing lightweight insulated pipe supports at scale can offer competitive pricing and ensure timely delivery, making the procurement process more efficient.

Conclusion

The design innovations in lightweight insulated pipe supports are transforming the pipeline industry, offering more cost-effective, durable, and energy-efficient solutions for industrial applications. By leveraging advanced materials, optimized structural designs, and improved thermal insulation properties, manufacturers are developing pipe support systems that meet the evolving needs of modern industries. Whether for energy, chemical, or manufacturing applications, lightweight insulated pipe supports provide a reliable and sustainable solution that enhances the safety and performance of pipeline systems.

As the demand for more efficient and eco-friendly pipeline solutions grows, the role of pipe support manufacturers will continue to be crucial in driving innovation and providing high-quality products for industrial applications.

References

GB/T 7714:Baetens R, Jelle B P, Gustavsen A. Aerogel insulation for building applications: A state-of-the-art review[J]. Energy and buildings, 2011, 43(4): 761-769.

MLA:Baetens, Ruben, Bjørn Petter Jelle, and Arild Gustavsen. "Aerogel insulation for building applications: A state-of-the-art review." Energy and buildings 43.4 (2011): 761-769.

APA:Baetens, R., Jelle, B. P., & Gustavsen, A. (2011). Aerogel insulation for building applications: A state-of-the-art review. Energy and buildings, 43(4), 761-769.

Hot Products

Hot Products

Contact Us

Contact Us

Contact:

Mobile:+86 +86 19133378808

Website:mingdepipe.com

Address: