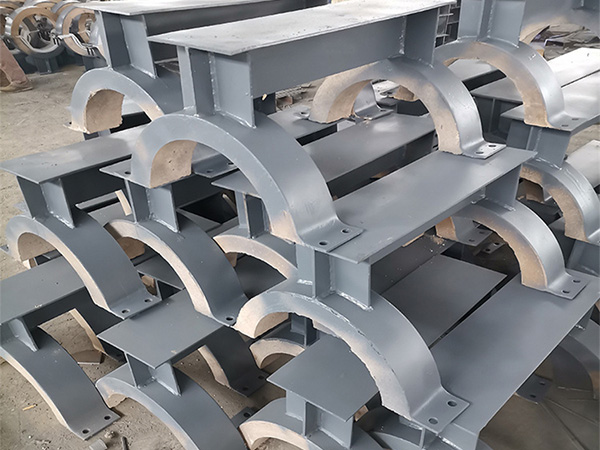

Fireproof and Heat-Resistant Insulated Bracket Solutions

Author:Mingde Time:2025-12-20 20:23:05 Click:51

The Importance of Pipeline Insulation Bracket Systems

Pipeline Insulation Bracket systems play a vital role in modern industrial piping infrastructure, especially in environments where fire safety and high-temperature resistance are critical. From energy facilities and chemical plants to commercial buildings and industrial processing lines, proper pipe support combined with thermal insulation protection ensures system stability, safety, and long-term efficiency.

Manufactured through controlled production processes and designed for large-volume applications, Pipeline Insulation Bracket solutions provide reliable support while maintaining insulation continuity. Their fireproof and heat-resistant properties make them essential components in demanding industrial and commercial settings.

What Is a Pipeline Insulation Bracket?

A Pipeline Insulation Bracket is a specialized pipe support component designed to carry the load of insulated pipelines while minimizing heat transfer and protecting insulation layers. Unlike standard pipe supports, insulated brackets integrate structural strength with thermal and fire-resistant performance.

From a manufacturing perspective, these brackets are produced using standardized designs and materials that support consistent quality across bulk production. This ensures compatibility with various insulation systems and pipeline diameters.

Key characteristics include:

·High load-bearing capacity

·Fire-resistant and heat-resistant materials

·Compatibility with insulation layers

·Suitability for large-scale industrial production

Why Fireproof and Heat Resistance Matter

1. Fire Safety in Industrial Environments

Fire risk is a major concern in facilities handling high-temperature fluids or flammable materials. Pipeline Insulation Bracket systems are designed to maintain structural integrity during fire exposure, reducing the risk of pipeline collapse or insulation failure.

Fire-resistant materials help prevent rapid heat transfer, allowing critical systems more time to remain operational or be safely shut down during emergencies.

2. Thermal Stability Under High Temperatures

In high-temperature piping systems, thermal expansion and continuous heat exposure can weaken traditional supports. Heat-resistant Pipeline Insulation Bracket designs help maintain stability by withstanding prolonged temperature stress without deformation.

This thermal stability supports consistent insulation performance and reduces maintenance requirements over time.

Applications of Fireproof and Heat-Resistant Insulated Brackets

Pipeline Insulation Bracket solutions are widely used across multiple industries due to their versatility and performance reliability.

Industrial and Energy Facilities

In power plants, refineries, and chemical processing facilities, insulated brackets support pipelines carrying steam, hot oil, or process fluids. Fireproof properties enhance safety, while heat resistance ensures long-term structural performance.

Commercial and Infrastructure Projects

Large commercial buildings and infrastructure projects rely on Pipeline Insulation Bracket systems for HVAC, district heating, and utility pipelines. Standardized production allows for efficient bulk supply to meet tight construction schedules.

Specialized High-Risk Environments

Facilities with elevated fire risk or extreme operating temperatures benefit from insulated brackets designed to meet strict safety and performance requirements. These environments demand materials and manufacturing consistency to ensure dependable operation.

Advantages Over Conventional Pipe Supports

Compared to traditional pipe supports, Pipeline Insulation Bracket solutions offer several advantages:

·Reduced thermal bridging

·Improved fire resistance

·Extended insulation lifespan

·Enhanced structural stability

By integrating insulation support into the bracket design, these systems improve overall piping efficiency and safety.

Manufacturing and Production Considerations

The performance of Pipeline Insulation Bracket systems is closely linked to manufacturing quality. Precision fabrication, material selection, and quality control processes ensure that each bracket meets load and thermal requirements.

Manufacturers with advanced production capabilities can deliver large quantities with uniform specifications, supporting bulk supply for industrial and commercial projects. This consistency is essential for maintaining system reliability across extensive pipeline networks.

Installation Efficiency and Long-Term Performance

Pipeline Insulation Bracket solutions are designed for straightforward installation, reducing labor time and minimizing the risk of insulation damage during assembly. Proper installation helps maintain insulation continuity and reduces thermal losses.

Over the long term, fireproof and heat-resistant brackets contribute to:

·Lower maintenance frequency

·Improved operational safety

·Stable insulation performance

These benefits make them a cost-effective choice for large-scale installations.

Supporting Safety and Engineering Standards

While specific regulations vary by region, Pipeline Insulation Bracket systems are commonly designed to align with industry safety and engineering standards related to fire resistance, load capacity, and thermal performance.

Manufacturing processes that emphasize standardization and traceability help ensure compliance with project requirements and quality expectations.

Conclusion: Reliable Pipeline Insulation Bracket Solutions for Demanding Applications

Pipeline Insulation Bracket solutions provide essential fireproof and heat-resistant support for modern piping systems. By combining structural strength with thermal protection, they enhance safety, efficiency, and durability across industrial and commercial applications.

Backed by standardized manufacturing processes, controlled production systems, and stable bulk supply capabilities, Pipeline Insulation Bracket products are well suited for large-scale projects requiring consistent performance and reliable delivery. Their role in supporting insulated pipelines makes them a critical component in high-temperature and fire-sensitive environments.

References

GB/T 7714:Callister Jr W D, Rethwisch D G. Materials science and engineering: an introduction[M]. John wiley & sons, 2020.

MLA:Callister Jr, William D., and David G. Rethwisch. Materials science and engineering: an introduction. John wiley & sons, 2020.

APA:Callister Jr, W. D., & Rethwisch, D. G. (2020). Materials science and engineering: an introduction. John wiley & sons.

Hot Products

Hot Products

Contact Us

Contact Us

Contact:

Mobile:+86 +86 19133378808

Website:mingdepipe.com

Address: