Optimization of Insulation Brackets for High-Flow Fluid Pipelines

Author:Mingde Time:2025-10-21 21:52:24 Click:190

Pipe Support Systems and Their Engineering Significance

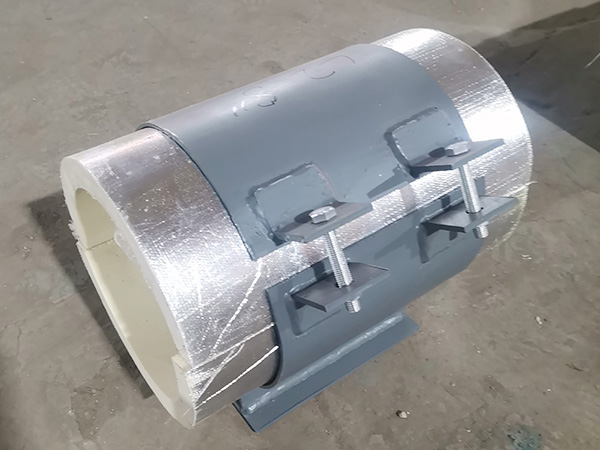

In the world of industrial piping, Pipe Support Systems form the backbone of mechanical stability and energy efficiency. Among their essential components, insulation brackets play a decisive role in maintaining temperature control and protecting pipelines carrying high-velocity fluids.

These brackets ensure that insulated pipelines remain structurally secure while preventing heat loss and reducing mechanical strain. With increasing global demand for efficient energy transport systems, China manufacturers have become leading suppliers of optimized insulation brackets—offering bulk-supply capabilities and proven expertise as direct production factories.

1. Why Insulation Brackets Matter in Pipeline Systems

Insulation brackets act as both thermal barriers and structural anchors. Their function extends beyond simple support—they maintain temperature balance, prevent corrosion under insulation, and absorb vibration stress from rapid fluid movement.

Main benefits include:

·Thermal stability through continuous insulation and minimized heat transfer.

·Mechanical balance under variable load conditions and flow-induced vibrations.

·Improved energy conservation by reducing heat leakage.

·Enhanced durability, protecting both pipe coatings and insulation materials.

In short, high-quality insulation brackets define the reliability and performance of a Pipe Support System operating under extreme thermal and pressure conditions.

2. Key Design Variables in Insulation Bracket Optimization

Optimizing insulation brackets requires a careful combination of material selection, geometry, and mechanical design. The performance of a Pipe Support System depends on several engineering factors:

a. Material Innovation

Modern designs increasingly adopt composite materials, glass-fiber reinforcements, and high-density polymer foams. These materials minimize heat conduction while maintaining compressive strength.

b. Load and Stress Analysis

Supports must handle both static weight and dynamic forces from pressure surges. Finite element modeling helps engineers design brackets that distribute loads evenly along the pipe.

c. Thermal Resistance

Low-conductivity liners and multilayer insulation assemblies prevent heat bridges, ensuring system efficiency even under fluctuating temperatures.

d. Corrosion and Fatigue Prevention

Advanced surface treatments, such as anti-corrosive coatings or polymeric layers, prevent degradation from condensation and environmental exposure.

Chinese Pipe Support System manufacturers have refined these parameters through R&D and digital simulation, offering customized solutions that balance strength, insulation performance, and production efficiency.

3. Precision Manufacturing through CNC and Automation

CNC machining technology has become a cornerstone of insulation bracket production. Automated systems ensure uniform geometry, consistent tolerance, and repeatable accuracy across bulk supply orders.

Modern China manufacturers integrate:

·CNC cutting and forming centers for high-dimensional accuracy.

·Automated foam injection systems for insulation uniformity.

·Laser measurement tools to verify bracket alignment and thickness.

·Digital inspection for real-time process control.

By combining automation with intelligent monitoring, manufacturers deliver reliable Pipe Support Systems that meet international specifications such as ASME B31 and ISO 9001.

4. Engineering Simulation and Optimization Testing

Computer-based modeling allows engineers to predict bracket behavior under thermal, mechanical, and environmental loads before mass production.

FEA (Finite Element Analysis) and CFD (Computational Fluid Dynamics) tools simulate:

·Temperature gradients along insulated sections.

·Expansion and contraction during operational cycles.

·Vibration responses in high-flow pipelines.

·Shear and bending stresses on bracket joints.

These data-driven optimizations help China manufacturers improve bracket strength while reducing unnecessary material use—leading to lighter, stronger, and more sustainable Pipe Support Systems.

5. China Manufacturers: Precision, Scale, and Reliability

Over the last decade, China’s industrial base has grown into a key global supplier for pipeline accessories and structural supports. In the field of Pipe Support Systems, Chinese factories are recognized for their technical innovation and large-scale production efficiency.

Their core advantages include:

·Factory-direct bulk supply, ensuring consistent quality and pricing transparency.

·Full material traceability and certification for export compliance.

·Comprehensive testing, including tensile, compression, and heat-resistance evaluation.

·Flexible customization, tailored to client specifications and environmental conditions.

Such attributes make China manufacturers a preferred partner for engineering firms, EPC contractors, and pipeline system integrators worldwide.

6. Future Directions in Pipe Support System Optimization

As global industries demand higher performance from energy infrastructure, Pipe Support Systems are evolving toward smarter, greener, and more integrated designs.

Emerging developments include:

·AI-driven optimization of bracket shapes for stress reduction.

·Digital twins for monitoring thermal loss and structural movement.

·Recyclable insulation materials to meet sustainability goals.

·Smart sensors for temperature and load feedback in real time.

The integration of digital technologies and eco-friendly materials will define the next generation of insulation brackets, further improving operational safety and energy conservation.

Conclusion: Building the Future of Pipe Support Systems

The evolution of insulation brackets exemplifies the broader transformation of Pipe Support Systems—from simple mechanical fixtures to precision-engineered, thermally optimized components.

China manufacturers, equipped with automation, digital testing, and bulk supply capacity, are driving this change globally. By merging innovation with manufacturing scale, they offer robust, cost-effective solutions that ensure both efficiency and reliability in modern high-flow pipeline networks.

In today’s competitive industrial landscape, the synergy between advanced materials, precise engineering, and large-scale production continues to shape the sustainable future of pipeline infrastructure.

References

GB/T 7714:Salem E A, Khalil M F, Sanhoury A S. Optimization of insulation thickness and emissions rate reduction during pipeline carrying hot oil[J]. Alexandria Engineering Journal, 2021, 60(3): 3429-3443.

MLA:Salem, Essam A., M. Farid Khalil, and Asmaa S. Sanhoury. "Optimization of insulation thickness and emissions rate reduction during pipeline carrying hot oil." Alexandria Engineering Journal 60.3 (2021): 3429-3443.

APA:Salem, E. A., Khalil, M. F., & Sanhoury, A. S. (2021). Optimization of insulation thickness and emissions rate reduction during pipeline carrying hot oil. Alexandria Engineering Journal, 60(3), 3429-3443.

Hot Products

Hot Products

Contact Us

Contact Us

Contact:

Mobile:+86 +86 19133378808

Website:mingdepipe.com

Address: