Smart Monitoring Pipe Insulation Brackets: The Future of Pipeline Support Systems

Author:Mingde Time:2025-10-24 18:35:02 Click:132

Intelligent Support for a Smarter Energy Era

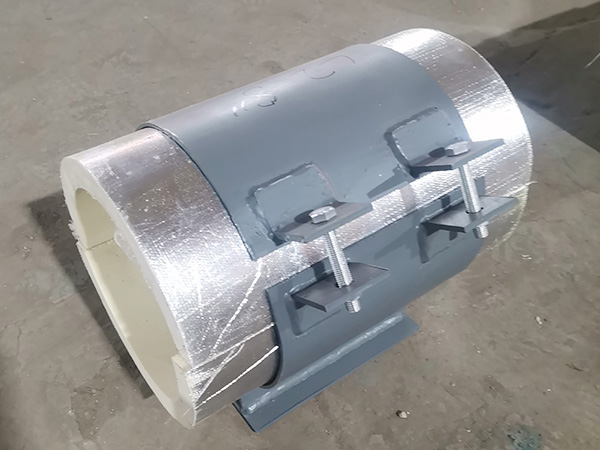

As industries worldwide shift toward digital and sustainable operations, the demand for intelligent Pipe Support Systems is rapidly expanding. Among the most transformative innovations are smart monitoring Pipe Insulation Brackets, which merge mechanical support with real-time digital sensing.

These advanced systems help maintain thermal efficiency, structural stability, and predictive maintenance—all in one integrated solution. Backed by the large-scale manufacturing capacity of China suppliers, bulk-supply smart pipe supports are becoming the backbone of modern energy infrastructure worldwide.

1. Redefining the Function of Pipe Insulation Brackets

Traditional pipe brackets were purely mechanical devices designed to bear loads and maintain insulation continuity. Today, the new generation of smart Pipe Insulation Brackets adds intelligence and interactivity.

Key Advantages Include:

·Continuous Monitoring: Sensors embedded within the support measure temperature, vibration, and mechanical stress in real time.

·Thermal Protection: Maintains insulation integrity to minimize heat loss in high- or low-temperature fluid pipelines.

·Predictive Maintenance: Early detection of abnormal stress or temperature drift prevents costly downtime.

·Extended Service Life: Reduced material fatigue and corrosion through optimized bracket design.

By combining insulation, structure, and intelligence, modern Pipe Support Systems improve both energy performance and operational safety.

2. How Smart Pipe Support Systems Enhance Energy Efficiency

Energy transportation networks—whether for steam, hydrogen, geothermal water, or district heating—depend on stable, insulated, and reliable supports.

Smart Pipe Insulation Brackets serve as a bridge between structural mechanics and digital energy management.

Applications Include:

·Geothermal Heating Pipelines: Retaining thermal balance in long-distance underground systems.

·Solar Thermal Power Plants: Supporting fluid transport pipes under continuous thermal expansion and contraction.

·District Heating and Cooling Networks: Ensuring uniform insulation performance across buried pipeline sections.

·Biofuel and Hydrogen Infrastructure: Monitoring stress under fluctuating flow and temperature conditions.

Across all these green energy projects, China manufacturers have become reliable bulk-supply partners, offering cost-effective smart bracket solutions for global energy clients.

3. The Technology Behind Smart Monitoring Pipe Supports

Integrating intelligent monitoring into Pipe Support Systems requires both engineering precision and digital innovation.

a. Material Design and Insulation Performance

High-strength composites such as phenolic foam, polyurethane, and fiberglass-reinforced plastic (FRP) provide superior insulation and corrosion resistance. These materials also support embedded sensor placement without thermal interference.

b. Sensor Integration and Connectivity

IoT sensors installed in the bracket measure temperature, vibration, and strain. Wireless data transmission technologies—LoRa, Bluetooth, or 5G—enable real-time cloud monitoring from remote control centers.

c. Data Analytics and Predictive Insights

Using AI algorithms, collected data can predict maintenance needs before faults occur, optimizing resource allocation and reducing repair costs.

By leveraging CNC precision production and intelligent assembly, China-based factories now produce bulk quantities of these sensor-integrated brackets for international energy projects.

4. China Manufacturers Driving Global Innovation

The manufacturing landscape in China has evolved dramatically—today’s China suppliers are not only producers but also technology innovators.

Manufacturing Advantages:

·CNC Automation: Ensures dimensional accuracy for custom bracket geometries.

·Integrated Sensor Assembly: Embeds monitoring hardware during molding for long-term stability.

·Quality Certification: Products meet ISO, EN, and ASME standards.

·Scalable Production: Enables bulk export supply with consistent performance.

This combination of digital engineering and industrial scale positions China manufacturers as global leaders in smart Pipe Support Systems.

5. Environmental and Operational Benefits

Smart monitoring Pipe Insulation Brackets contribute directly to energy conservation and sustainability goals.

·Reduced Heat Loss: Maintains pipeline efficiency and lowers fuel consumption.

·Lower Carbon Footprint: Supports global decarbonization targets.

·Extended Equipment Lifespan: Detects mechanical fatigue early, preventing structural failure.

·Maintenance Optimization: Data-driven insights minimize manual inspections and maintenance costs.

By integrating digital monitoring with physical design, these systems align perfectly with the principles of Industry 4.0 and the transition to low-carbon energy networks.

6. Future Trends: Digital Intelligence Meets Mechanical Engineering

The future of Pipe Support Systems will be increasingly autonomous, adaptive, and eco-friendly.

Emerging innovations include:

·Self-powered sensors using thermoelectric or piezoelectric energy harvesting.

·AI-driven support adjustment for real-time load balancing.

·Recyclable, lightweight composites that further cut environmental impact.

·Digital twins that simulate system performance before installation.

Through partnerships with research institutions and technology firms, China manufacturers are already testing prototypes for these next-generation smart brackets—designed for both industrial and renewable energy infrastructure.

Conclusion: Smarter Pipe Support Systems, Stronger Energy Networks

The integration of monitoring, insulation, and mechanical stability marks a new era in pipeline engineering.

Smart Pipe Insulation Brackets are not just supports—they are intelligent guardians ensuring safety, efficiency, and longevity in every pipeline system.

With China manufacturers leading the bulk-supply of high-quality smart brackets, industries worldwide can now adopt affordable and innovative solutions tailored for modern energy challenges.

From smart data to sustainable design, the evolution of Pipe Support Systems reflects the future of global infrastructure—intelligent, efficient, and environmentally responsible.

References

GB/T 7714:Keçebaş A, Alkan M A, Bayhan M. Thermo-economic analysis of pipe insulation for district heating piping systems[J]. Applied Thermal Engineering, 2011, 31(17-18): 3929-3937.

MLA:Keçebaş, Ali, Mehmet Ali Alkan, and Mustafa Bayhan. "Thermo-economic analysis of pipe insulation for district heating piping systems." Applied Thermal Engineering 31.17-18 (2011): 3929-3937.

APA:Keçebaş, A., Alkan, M. A., & Bayhan, M. (2011). Thermo-economic analysis of pipe insulation for district heating piping systems. Applied Thermal Engineering, 31(17-18), 3929-3937.

Hot Products

Hot Products

Contact Us

Contact Us

Contact:

Mobile:+86 +86 19133378808

Website:mingdepipe.com

Address: