Corrosion-Resistant Brackets for Harsh Environments

Author:Mingde Time:2025-11-13 16:04:56 Click:142

Defending Pipeline Integrity Against Corrosion

In harsh industrial or coastal settings, corrosion is one of the most damaging forces affecting metal structures. Pipeline systems are particularly vulnerable, as their supporting brackets often face exposure to moisture, salt, and temperature fluctuations.

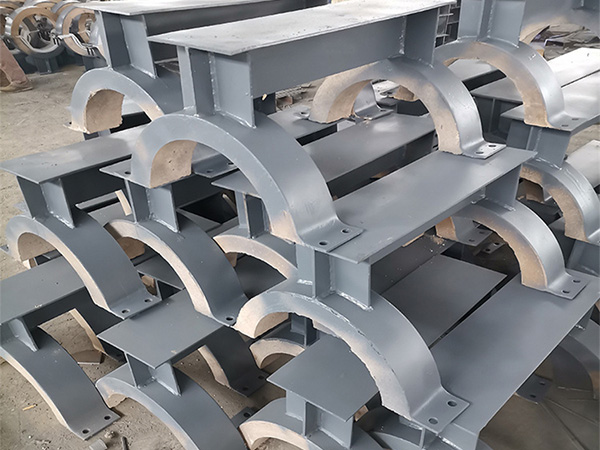

A high-quality Pipeline Insulation Bracket is more than just a support—it’s a safeguard that keeps your piping system stable and insulated over years of operation. Built by an experienced manufacturer with large-scale production capacity, corrosion-resistant brackets deliver the reliability demanded by heavy industry.

1. The Hidden Threat of Corrosion

Corrosion is a gradual but relentless process. Over time, it can weaken metal supports, causing insulation failure and even system instability. In pipelines, once rust begins to spread across brackets, structural integrity declines rapidly.

This can lead to:

·Reduced load-bearing capacity

·Insulation gaps or thermal loss

·Increased vibration and noise

·Frequent maintenance shutdowns

Choosing corrosion-resistant Pipeline Insulation Brackets is essential to ensuring the long-term safety and efficiency of any piping network.

2. Design Strategies for Corrosion Prevention

To withstand harsh environments, modern bracket systems are engineered with durability in mind. Effective anti-corrosion design includes several key strategies:

First, material selection plays a decisive role. Stainless steel, galvanized steel, and aluminum alloys are common choices for resisting oxidation and chemical attack. In highly aggressive environments, non-metallic composites are sometimes used.

Second, surface protection is essential. Coatings such as epoxy, powder finish, or hot-dip galvanizing create a durable barrier between the metal and the environment.

Third, geometry and drainage design reduce water accumulation. Brackets shaped to allow air circulation and quick moisture release are far less likely to trap corrosive agents.

Lastly, thermal isolation—using insulation pads or non-metallic inserts—prevents temperature bridging and condensation, both of which accelerate corrosion.

3. Materials Suitable for Harsh Conditions

For pipelines exposed to harsh climates, material choice determines the bracket’s lifespan. Stainless steel provides long-term corrosion resistance in marine or chemical settings. Galvanized steel offers strong mechanical support at a lower cost for outdoor systems.

In situations where weight reduction is important, aluminum brackets combine strength and corrosion resistance effectively. Composite or FRP brackets, while more specialized, are ideal for environments with extreme chemical exposure.

A manufacturer with efficient production facilities can combine these materials into customized solutions—balancing performance, cost, and environmental demands.

4. Industry Standards That Guarantee Quality

Corrosion resistance is not a claim—it must be verified through testing. Reputable manufacturers ensure every Pipeline Insulation Bracket meets recognized international standards such as:

·ASTM B117 (Salt Spray Test for corrosion resistance)

·ISO 9227 (Accelerated corrosion simulation)

·ISO 12944 (Protective coating classification)

Compliance with these standards ensures that the brackets remain structurally sound after years of exposure to moisture and chemical environments.

5. Engineering Innovations Improving Durability

The latest bracket designs incorporate new technologies to enhance protection. Some integrate self-draining features that prevent water retention, while others use non-conductive insulation layers to block galvanic corrosion.

Advanced coatings can even indicate corrosion visually by changing color, allowing early maintenance before damage occurs. Such improvements reflect the evolution of manufacturing and production processes focused on durability and safety.

6. Why Choose a Professional Manufacturer

Partnering with a dedicated Pipeline Insulation Bracket manufacturer provides significant benefits beyond simple product supply. Experienced manufacturers ensure:

·Consistent quality through controlled production

·Material and size customization for each project

·Bulk supply for industrial-scale installations

·Technical support from design to installation

These advantages guarantee that the brackets are not only strong and corrosion-resistant but also perfectly matched to your system’s operational environment.

7. Typical Applications

Corrosion-resistant brackets are used wherever pipes face environmental challenges. Common applications include:

·Offshore oil and gas platforms

·Chemical processing facilities

·Marine and ship piping systems

·Power generation plants

·Building and HVAC systems exposed to weather

In all these fields, durable Pipeline Insulation Brackets protect critical infrastructure and reduce lifecycle costs.

8. Extending Service Life Through Maintenance

Even the strongest brackets need correct installation and periodic care. Use corrosion inhibitors or protective lubricants during assembly, ensure that different metals do not contact directly, and inspect brackets regularly for surface damage or signs of rust.

These preventive steps will significantly extend the lifespan of your support system.

Conclusion: Long-Term Reliability Through Better Design

When it comes to pipeline performance, the bracket system is often the unsung hero. A corrosion-resistant Pipeline Insulation Bracket, engineered by a professional manufacturer with modern production capability, can extend the service life of entire piping networks.

By investing in high-quality, corrosion-proof brackets today, you ensure safer operations, fewer maintenance issues, and better long-term efficiency—no matter how harsh the environment may be.

References

GB/T 7714:Ding H, Ji J C. Vibration control of fluid-conveying pipes: a state-of-the-art review[J]. Applied Mathematics and Mechanics, 2023, 44(9): 1423-1456.

MLA:Ding, Hu, and J. C. Ji. "Vibration control of fluid-conveying pipes: a state-of-the-art review." Applied Mathematics and Mechanics 44.9 (2023): 1423-1456.

APA:Ding, H., & Ji, J. C. (2023). Vibration control of fluid-conveying pipes: a state-of-the-art review. Applied Mathematics and Mechanics, 44(9), 1423-1456.

Hot Products

Hot Products

Contact Us

Contact Us

Contact:

Mobile:+86 +86 19133378808

Website:mingdepipe.com

Address: