Designing Pipe Insulation Brackets for Offshore Platforms

Author:Mingde Time:2025-10-11 21:06:32 Click:95

Offshore energy platforms demand components that can endure harsh conditions while maintaining performance. Among these, the Pipe Insulation Bracket serves as a critical support structure for insulated pipelines. By keeping insulation intact and ensuring stability, these brackets reduce energy losses and enhance operational safety. In environments exposed to seawater, extreme pressures, and fluctuating temperatures, properly designed pipe insulation brackets are essential. For projects requiring reliability, partnering with a China supplier that provides bulk supply proof guarantees consistent quality and smooth project execution.

Role of Pipe Insulation Brackets in Offshore Operations

Preserving Thermal Integrity

Insulated pipes are used to transport oil, gas, and steam efficiently. Without suitable support, insulation can shift or deteriorate, causing heat loss. Brackets ensure insulation remains secure and functional over the pipeline’s lifespan.

Ensuring Mechanical Support

The weight of pipelines, especially when filled and insulated, requires robust support. Pipe insulation brackets distribute loads evenly and protect pipelines from stress or sagging that may compromise system safety.

Adapting to Harsh Environments

Offshore facilities operate in highly corrosive conditions. Brackets made from stainless steel, galvanized steel, or advanced composites withstand saline exposure, high humidity, and extreme climate variations.

Essential Design Factors

1. Choice of Materials

Selecting the right material ensures resilience against corrosion and mechanical stress:

·Stainless Steel for high corrosion resistance.

·Galvanized Steel as a cost-conscious option with surface protection.

·Composite Solutions for lightweight durability and minimized thermal bridging.

2. Load Requirements

Engineering calculations must confirm that brackets can handle the combined weight of insulation and pipeline content, preventing deformation or mechanical damage.

3. Compatibility with Insulation

The bracket should work seamlessly with insulation layers, minimizing cold or heat bridging while maintaining secure placement.

4. Vibration Protection

Marine operations involve continuous vibrations from equipment and waves. Brackets must integrate features to absorb shocks and avoid fatigue-related failures.

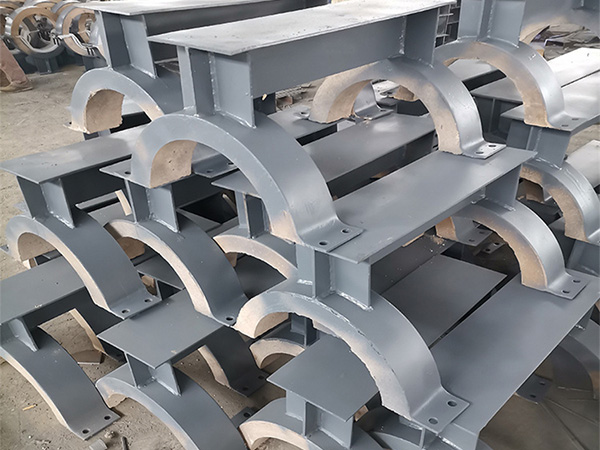

Manufacturing Pipeline of Pipe Insulation Brackets

Cutting and Forming

Raw materials are precisely cut and shaped using advanced machinery to achieve accurate dimensions.

Surface Finishing

Coatings like epoxy, galvanization, or powder treatments shield brackets from corrosion and extend service life.

Assembly & Welding

Brackets are welded or bolted with strict tolerances to ensure structural consistency.

Quality Validation

Before delivery, each bracket undergoes dimensional inspections, strength testing, and surface checks. Reputable China manufacturers often provide certificates and bulk supply proof, assuring customers of compliance and traceability.

Benefits of Pipe Insulation Brackets

·Reliability in Harsh Settings: Resilient against salt spray, humidity, and extreme climates.

·Energy Conservation: Maintain insulation effectiveness and reduce heat transfer losses.

·Safety Assurance: Minimize risk of pipeline failure under high loads.

·Extended Durability: Designed for long operational life with minimal upkeep.

Offshore Application Scenarios

Hydrocarbon Transport

Brackets support insulated pipelines carrying crude oil and natural gas across subsea and topside structures.

Steam and Process Fluids

They secure high-temperature pipelines, ensuring thermal efficiency in power generation and recovery processes.

Chemical and Refinery Systems

Provide durable support for pipes transporting corrosive or hazardous chemicals in offshore plants.

Value of Choosing Verified China Manufacturers

Selecting a China manufacturer that offers bulk supply proof ensures that large-scale offshore projects receive consistent quality and reliable shipments. With offshore builds often requiring thousands of brackets, a dependable supplier helps reduce delays and cost risks while meeting international compliance standards.

Practical Guidance for Engineers

·Confirm Materials: Validate corrosion resistance and marine-grade performance.

·Independent Testing: Third-party verification boosts confidence in quality.

·Protective Storage: Maintain coating integrity during transport and staging.

·Regular Maintenance: Scheduled checks prolong reliability and safety.

Conclusion

The Pipe Insulation Bracket is fundamental to the efficiency and safety of offshore pipeline systems. By combining smart design, corrosion-resistant materials, and robust load capacity, these brackets guarantee stability in demanding marine settings. Collaborating with a trusted China supplier that provides bulk supply proof secures not only consistent quality but also timely delivery for complex offshore projects. For long-lasting reliability, energy efficiency, and operational safety, pipe insulation brackets remain an essential component of offshore infrastructure.

References

GB/T 7714:Cao Q, Pojtanabuntoeng T, Esmaily M, et al. A review of corrosion under insulation: a critical issue in the oil and gas industry[J]. Metals, 2022, 12(4): 561.

MLA:Cao, Qing, et al. "A review of corrosion under insulation: a critical issue in the oil and gas industry." Metals 12.4 (2022): 561.

APA:Cao, Q., Pojtanabuntoeng, T., Esmaily, M., Thomas, S., Brameld, M., Amer, A., & Birbilis, N. (2022). A review of corrosion under insulation: a critical issue in the oil and gas industry. Metals, 12(4), 561.

Hot Products

Hot Products

Contact Us

Contact Us

Contact:

Mobile:+86 +86 19133378808

Website:mingdepipe.com

Address: