Energy Efficiency Certification for Insulated Pipeline Components

Author:Mingde Time:2026-01-25 09:02:17 Click:160

Why Energy Efficiency Matters in Pipeline Systems

Energy efficiency has become a critical requirement in modern industrial infrastructure. Pipelines transporting steam, hot water, oil, gas, and chemicals lose significant energy through heat transfer if not properly insulated. These losses increase operational costs, reduce process stability, and raise environmental impact.

Insulated pipeline components are designed to minimize thermal leakage, and their performance is often verified through energy efficiency certification programs. A reliable pipeline insulation bracket manufacturer understands that efficiency does not depend only on insulation materials, but also on how brackets support, isolate, and protect the pipeline from thermal bridges.

Through standardized production in factory environments, manufacturers ensure that insulation brackets perform consistently across large-scale installations, helping operators reduce energy waste and improve system sustainability.

The Function of Pipeline Insulation Brackets

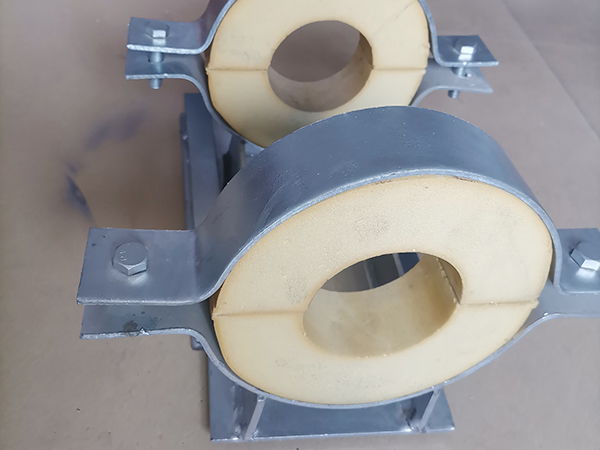

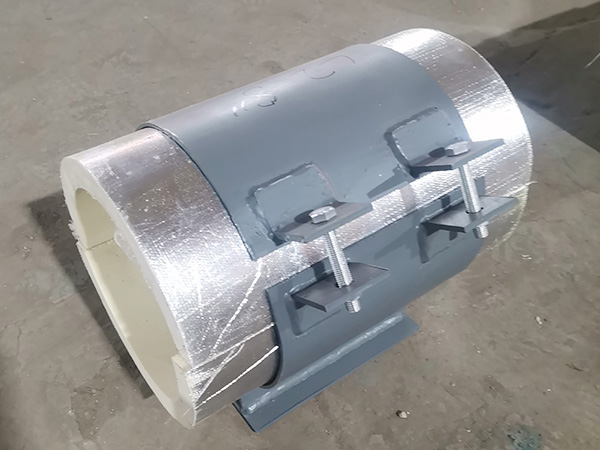

A pipeline insulation bracket plays a structural and thermal role within insulated pipeline systems. It supports pipe weight, maintains spacing, and prevents insulation compression while minimizing heat transfer at support points.

Without proper bracket design, even the best insulation materials can fail because direct metal contact creates thermal bridges. These bridges allow heat to escape, reducing overall system efficiency. Modern insulation brackets incorporate load-bearing cores with low thermal conductivity layers to preserve insulation continuity.

Professional manufacturer production integrates mechanical strength with thermal isolation, ensuring brackets provide both structural safety and energy-saving performance in real operating environments.

Role of a Manufacturer in Certified Production

Energy efficiency certification is not achieved by accident. It requires consistent design, controlled materials, and validated manufacturing processes. A qualified pipeline insulation bracket manufacturer embeds certification requirements into its production workflow.

Factory production ensures surface preparation, material forming, bonding, and finishing are performed under standardized conditions. This repeatability is essential for certification audits, where inspectors review both product performance and manufacturing traceability.

Bulk supply from factory lines also guarantees that large infrastructure projects receive uniform brackets that meet the same efficiency and safety specifications across the entire pipeline network.

Key Energy Efficiency Certification Standards

Energy efficiency certification for insulated pipeline components typically references thermal conductivity, mechanical stability, and durability. Standards often focus on reducing heat loss at pipe supports and connection points.

Certification systems evaluate how well insulated components prevent heat transfer under operational temperatures and loads. Brackets are tested for compression strength, thermal resistance, and long-term deformation.

By aligning production with certification criteria, a pipeline insulation bracket manufacturer ensures that its products contribute to overall pipeline efficiency rather than becoming weak points in the thermal system.

Thermal Performance and Heat Loss Control

Thermal performance is the core metric behind energy efficiency certification. Heat loss at pipe supports can account for a significant portion of total system inefficiency if not properly controlled.

Insulation brackets designed with composite structures interrupt conductive heat paths. They distribute mechanical loads while maintaining insulation thickness. This approach reduces localized heat leakage and protects surrounding insulation materials from crushing.

Factory-controlled production allows consistent geometry and material distribution, enabling every bracket to deliver predictable thermal resistance in service.

Material Selection for Insulated Components

Material choice directly affects the energy performance of pipeline insulation brackets. Structural cores often use high-strength steel for load capacity, while thermal isolation layers rely on low-conductivity composites or engineered polymers.

Surface treatments also influence durability and resistance to moisture, chemicals, and temperature cycling. Materials must retain both strength and insulation properties over long service periods.

A professional pipeline insulation bracket manufacturer integrates material testing into production, ensuring each batch meets both mechanical and thermal performance targets required for certified systems.

Factory Production and Quality Inspection

Energy efficiency certification depends heavily on quality control. During factory production, pipeline insulation brackets undergo inspection at multiple stages, including dimensional checks, load testing, and thermal performance verification.

Surface finishing, bonding quality, and structural alignment are inspected to prevent defects that could compromise efficiency. Production traceability ensures that each bracket can be linked to specific manufacturing conditions and material lots.

Bulk supply from factory environments allows project managers to deploy large volumes of certified components without variation, supporting long-term energy-saving goals across entire pipeline installations.

Applications Across Industrial Sectors

Certified insulated pipeline components are used across a wide range of industries. In power generation, insulation brackets reduce heat loss in steam systems. In oil and gas, they protect pipelines carrying high-temperature fluids. In district heating, they preserve energy from source to endpoint.

Chemical processing plants rely on insulation brackets to maintain stable temperatures while ensuring mechanical safety. In each application, manufacturer production and factory bulk supply allow standardized installation and predictable thermal performance.

Conclusion: Choosing Certified Pipeline Insulation Brackets

Energy efficiency certification plays a vital role in modern pipeline engineering. Properly designed and manufactured pipeline insulation brackets help minimize thermal bridges, reduce heat loss, and improve operational sustainability.

By working with a professional pipeline insulation bracket manufacturer supported by integrated production systems and reliable factory bulk supply, project owners gain consistent quality, certified performance, and long-term cost efficiency.

Ultimately, insulated pipeline components are more than structural supports—they are essential elements in energy management, safety assurance, and environmental responsibility across industrial infrastructure projects.

References

GB/T 7714:Xu M, Gao M, Yang R, et al. Economic Optimization of Thermal Insulation Thickness for Insulated and Electrically Traced Pipelines in Drilling Applications[J]. Processes, 2024, 12(7).

MLA:Xu, Meng, et al. "Economic Optimization of Thermal Insulation Thickness for Insulated and Electrically Traced Pipelines in Drilling Applications." Processes 12.7 (2024).

APA:Xu, M., Gao, M., Yang, R., Wang, K., & Yuan, Z. (2024). Economic Optimization of Thermal Insulation Thickness for Insulated and Electrically Traced Pipelines in Drilling Applications. Processes, 12(7).

Hot Products

Hot Products

Contact Us

Contact Us

Contact:

Mobile:+86 +86 19133378808

Website:mingdepipe.com

Address: