Energy-Efficient Pipeline Insulation Brackets

Author:Mingde Time:2025-11-02 12:46:22 Click:113

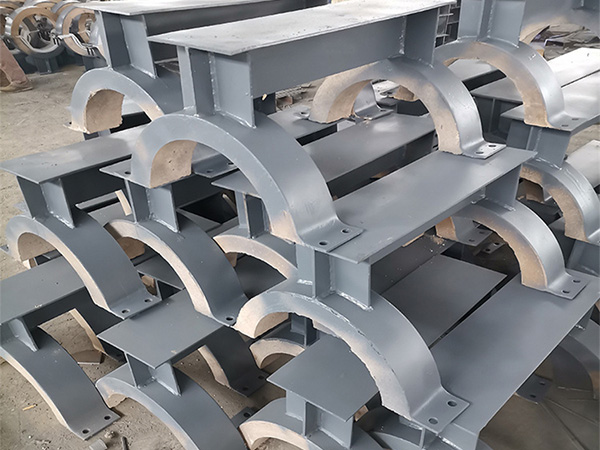

In industrial and energy systems, thermal management is essential for maintaining operational efficiency. While insulation materials receive much of the attention, the pipeline insulation bracket—the component that supports insulated pipelines and prevents heat transfer—is just as critical.

Well-designed insulation brackets help minimize heat loss, extend service life, and maintain system safety. As a China-based Pipeline Insulation Bracket manufacturer offering bulk supply, we integrate advanced materials, mechanical design, and energy-efficiency engineering into every product to meet the performance needs of global industries.

1. Choosing the Right Materials for Thermal and Structural Performance

The foundation of an energy-efficient insulation bracket lies in its material composition. The goal is to achieve maximum strength with minimal thermal conductivity.

Common material combinations include:

·Stainless steel frames for structural durability and corrosion resistance.

·Composite materials such as fiberglass or reinforced polymers for thermal insulation.

·Polyurethane or phenolic inserts to act as thermal breaks.

An effective design ensures that the bracket supports the pipeline’s load without forming a thermal bridge. Many Chinese manufacturers conduct performance simulations and heat-transfer testing to confirm that each bracket meets both structural and thermal requirements before mass production.

2. Optimizing Structural Geometry for Load and Energy Efficiency

An insulation bracket must provide stable support across varying pipeline diameters and operating conditions. Poorly balanced designs can deform insulation or cause vibration, leading to energy leakage and mechanical wear.

Engineers often apply finite element analysis (FEA) to refine bracket geometry, ensuring:

·Even load distribution across the insulation surface.

·Resistance to dynamic stress and vibration.

·Easy alignment with pipe expansion and contraction.

These optimizations create a system that maintains insulation integrity even under high-pressure or high-temperature operation—critical for energy-efficient performance.

3. Reducing Thermal Bridging and Energy Loss

Thermal bridging occurs when conductive materials (like metal brackets) allow heat to escape or enter the system. In high-temperature or cryogenic pipelines, even small bridges can result in significant energy loss.

To minimize this:

·Incorporate non-metallic isolators or sleeves between metal parts and pipes.

·Use multi-layer composite brackets that combine rigid strength with insulation properties.

·Limit direct metal-to-metal contact wherever possible.

These strategies help maintain thermal continuity, ensuring that insulation performance is not compromised by the support system.

4. Corrosion Control and Surface Treatment

In environments exposed to moisture, chemicals, or temperature fluctuations, corrosion protection becomes a key factor in the long-term performance of insulation brackets.

Reliable manufacturers use:

·Hot-dip galvanizing or powder coating to protect metal surfaces.

·Epoxy or fluoropolymer coatings for chemical resistance.

·Corrosion-resistant hardware to ensure system integrity.

A Chinese insulation bracket supplier with advanced coating technology can provide pre-treated components that extend lifespan, reduce maintenance, and retain energy efficiency under demanding conditions.

5. Installation Flexibility and Maintenance Accessibility

Energy efficiency is not only a design outcome but also depends on proper installation. Brackets should be modular, adjustable, and easy to inspect.

An ideal system design includes:

·Adjustable clamp configurations for various insulation thicknesses.

·Quick-release designs for simplified maintenance.

·Standardized components to reduce installation time.

This practical approach minimizes field errors, ensures insulation continuity, and maintains consistent energy-saving performance throughout the system’s lifecycle.

6. Compliance and International Standards

To guarantee performance and safety, all pipeline insulation brackets should comply with recognized international standards, such as:

·ASME B31.1 / B31.3 (Process Piping Systems)

·ISO 9001 / ISO 14692 (Quality and Composite Standards)

·EN 13480 (Industrial Piping Applications)

Manufacturers who operate under these certifications ensure consistent product quality, traceability, and energy-efficient design across global projects.

7. Sustainability and Lifecycle Optimization

Sustainability has become a key element of industrial design. Energy-efficient brackets not only save power but also reduce waste and support long-term environmental goals.

Modern manufacturers are moving toward:

·Recyclable materials with lower embodied energy.

·Coatings free from heavy metals or VOCs.

·Design-for-disassembly concepts that simplify recycling.

By partnering with a Chinese bulk supplier that embraces sustainable manufacturing, buyers can ensure they are investing in both performance and environmental responsibility.

Conclusion

An energy-efficient pipeline system is the result of precise engineering—from insulation materials to bracket design. The Pipeline Insulation Bracket is a small but powerful component that safeguards thermal efficiency, structural stability, and long-term performance.

As a leading Chinese manufacturer and large-scale supplier, we combine advanced materials science, simulation-based design, and strict quality control to deliver reliable insulation brackets for global industrial applications. Every product reflects our commitment to efficiency, durability, and sustainable engineering—ensuring your pipeline systems perform at their best with minimal energy waste.

References

GB/T 7714:Porzuczek J. Comparative study on selected insulating materials for industrial piping[J]. Materials, 2024, 17(7): 1601.

MLA:Porzuczek, Jan. "Comparative study on selected insulating materials for industrial piping." Materials 17.7 (2024): 1601.

APA:Porzuczek, J. (2024). Comparative study on selected insulating materials for industrial piping. Materials, 17(7), 1601.

Hot Products

Hot Products

Contact Us

Contact Us

Contact:

Mobile:+86 +86 19133378808

Website:mingdepipe.com

Address: