New Pipeline Insulation Support Materials: Enhancing Thermal Insulation Performance for Energy Efficiency

Author:Mingde Time:2025-07-23 03:02:48 Click:95

Introduction: The Importance of Pipeline Insulation Supports in Industry

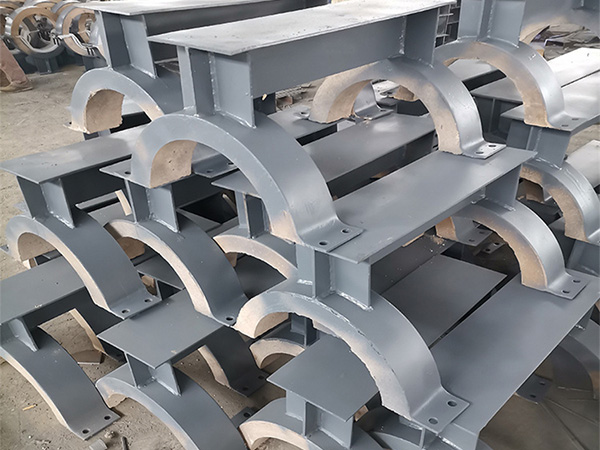

Pipeline insulation supports (Pipe Supports) are critical components in many industries, including oil and gas, power generation, and HVAC systems. Their primary function is to support and secure pipeline systems while providing effective thermal isolation to minimize energy loss. In industrial pipeline systems, heat transfer is a significant concern, and the thermal insulation performance of the pipeline directly impacts energy consumption and equipment efficiency. Therefore, developing high-performance and innovative pipeline insulation support materials is key to improving industrial energy efficiency.

Challenges with Traditional Pipeline Support Materials

Traditional pipeline support materials, such as metals like steel or aluminum alloys, typically offer good mechanical properties but fall short in thermal insulation. Especially in high-temperature environments, these materials tend to conduct heat, leading to pipeline heat loss. Because traditional materials do not provide sufficient thermal insulation, additional insulation layers are often required, which increases the overall system weight and complexity.

Moreover, as energy costs rise, industrial companies face increasing pressure to improve energy efficiency, making traditional pipeline support materials inadequate in meeting the demand for effective heat isolation.

Technological Breakthroughs in New Insulation Support Materials

With advancements in material science, a variety of new pipeline insulation support materials have emerged. These new materials not only enhance the thermal insulation performance of pipeline systems but also excel in terms of weight, corrosion resistance, and cost efficiency.

One emerging material is composite materials. These are typically composed of two or more different materials, combining the advantages of each while overcoming the limitations of individual materials. For example, ceramic particles within composite materials can significantly improve insulation performance, while polymer materials enhance the material’s toughness and durability.

Another breakthrough is the development of vacuum insulation materials (VIM). These materials offer far superior thermal insulation performance compared to traditional insulation materials, allowing for more efficient heat isolation in a smaller volume. When applied in pipeline supports, vacuum insulation materials significantly reduce heat loss and improve overall energy efficiency.

Key Technological Factors for Enhancing Thermal Insulation Performance

Several technological factors play a critical role in enhancing the thermal insulation performance of pipeline insulation supports:

1.Thermal Conductivity: The thermal conductivity of a material determines its insulation effectiveness. Materials with low thermal conductivity effectively block heat transfer, minimizing energy loss.

2.High-Temperature Resistance: Pipeline systems working in high-temperature environments require materials with excellent high-temperature resistance. New composite and ceramic materials maintain stable performance at high temperatures, preventing heat loss and material degradation.

3.Lightweight: Materials that are lightweight, yet provide effective thermal insulation, reduce the overall weight of the support system, simplifying installation and reducing the load on pipeline systems.

4.Corrosion Resistance: Pipeline supports are often exposed to humid or corrosive environments, so new materials must exhibit superior corrosion resistance to extend the lifespan of the system.

How to Select the Right Pipeline Insulation Support Materials

When choosing the appropriate pipeline insulation support materials, several factors should be considered:

·Pipeline Operating Temperature: Different temperature environments place varying demands on the material properties of pipeline supports.

·Thermal Load on the Pipeline: Select materials that optimize insulation based on the pipeline’s thermal load to ensure the best performance.

·External Environmental Factors: If the pipeline operates in corrosive conditions, materials with excellent corrosion resistance should be chosen to prevent early degradation of the support system.

·Budget and Cost Control: New insulation support materials may come at a higher initial cost, so it is important to assess long-term energy savings and maintenance costs when choosing the material.

Conclusion: Choosing the Best Pipeline Insulation Support Material for Efficiency and Safety

As industries continue to demand higher energy efficiency, the development of new pipeline insulation support materials has been a game-changer. Technologies such as composite materials and vacuum insulation materials offer significant improvements in thermal insulation, reducing heat loss while enhancing system efficiency. Choosing the right material can optimize pipeline performance, lower energy consumption, and enhance system safety.

When selecting pipeline supports, it’s essential to understand the characteristics and benefits of different materials, assess the specific environmental conditions and needs of the pipeline, and strike a balance between cost and performance. Proper material selection can significantly boost operational efficiency and contribute to sustainable industrial practices.

Closing Summary:

In practice, selecting the right pipeline insulation support material not only enhances thermal performance but also reduces energy losses, simplifies installation, and improves safety. With ongoing advancements in material technology, the future of pipeline insulation is moving toward more efficient and cost-effective solutions that help industries optimize their energy use while maintaining high performance and durability.

References

GB/T7714:Di Giacomo Jr L, Stinson J R. Piping supports[J]. Part A: Piping Fundamentals, 2000.

MLA:Di Giacomo Jr, L., and J. R. Stinson. "Piping supports." Part A: Piping Fundamentals (2000).

APA:Di Giacomo Jr, L., & Stinson, J. R. (2000). Piping supports. Part A: Piping Fundamentals.

Hot Products

Hot Products

Contact Us

Contact Us

Contact:

Mobile:+86 +86 19133378808

Website:mingdepipe.com

Address: