Industrial-Grade Pipeline Insulation Supports: Meeting Design Standards for High-Pressure Environments

Author:Mingde Time:2025-07-31 16:31:13 Click:138

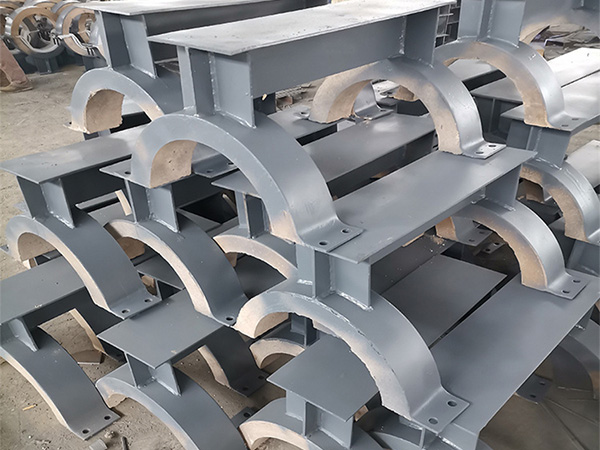

Introduction: The Role of Pipe Supports in High-Pressure Environments

In industrial applications, pipeline systems often operate under extreme conditions, including high temperatures, high pressures, and corrosive environments. To maintain system integrity and energy efficiency, the proper selection and installation of pipeline insulation supports (or pipe supports) are crucial. These supports help secure pipelines while providing thermal insulation, which reduces heat loss and improves energy efficiency.

In high-pressure systems, the stakes are even higher. Incorrectly designed or installed pipe supports can lead to pipeline failure, energy inefficiency, and costly downtime. This article delves into the critical design standards for industrial-grade pipeline insulation supports and offers insights into the best practices for ensuring they meet the demanding requirements of high-pressure environments.

The Importance of Proper Pipe Support Design in High-Pressure Environments

Pipeline systems that operate under high pressure require specific considerations when it comes to pipe support design. Unlike standard environments, high-pressure systems involve more significant forces and thermal loads, making it essential for supports to be designed to withstand these stresses while maintaining insulation performance.

Key considerations for industrial-grade pipe supports in high-pressure environments include:

·Strength and Load-Bearing Capacity: The supports must be capable of handling the high mechanical loads exerted by the pressure within the pipeline.

·Thermal Insulation Performance: High-pressure pipelines often carry hot substances, requiring effective insulation to prevent heat loss and maintain system efficiency.

·Corrosion Resistance: Given the harsh conditions, the materials used for pipe supports must be resistant to corrosion to avoid degradation over time.

·Durability and Longevity: The supports must be designed for long-term use, with minimal maintenance required, especially in systems where replacement is costly or challenging.

Key Design Standards for High-Pressure Pipeline Insulation Supports

1. Material Selection for Durability and Strength

The material chosen for pipeline insulation supports plays a critical role in the system’s overall performance. In high-pressure environments, the material must be both mechanically strong and thermally efficient. Common materials used for industrial-grade pipe supports include:

·Stainless steel: Known for its strength and corrosion resistance, stainless steel is often used in high-pressure systems that also require resistance to harsh chemicals and temperatures.

·Alloy steels: These materials offer superior strength at high temperatures, making them suitable for extreme pressure applications.

·Composite materials: These materials combine the benefits of both metal and non-metal elements, offering lightweight solutions without compromising thermal insulation and mechanical strength.

2. Thermal Insulation Performance

The effectiveness of thermal insulation in high-pressure pipeline systems is vital for reducing energy loss and maintaining system efficiency. Inadequate insulation can result in energy wastage, as heat loss can alter the pipelines operational conditions. Insulation materials used in high-pressure systems must offer:

·Low thermal conductivity to reduce heat loss.

·High-temperature resistance to withstand thermal expansion without degradation.

·Durability to maintain insulation performance over time in extreme conditions.

Common insulation materials used for high-pressure pipelines include mineral wool, ceramic fibers, and vacuum insulation materials (VIM), which provide superior heat retention with minimal weight.

3. Pressure Resistance and Flexibility

The design of pipe supports must also account for the high-pressure forces exerted on the pipeline. Pipe supports need to be flexible enough to accommodate thermal expansion while maintaining structural integrity. Supports that are too rigid could cause stress concentration in certain areas of the pipeline, leading to potential failure. Therefore, pipe supports must:

·Accommodate thermal expansion of the pipeline, allowing for movement due to temperature fluctuations.

·Distribute loads evenly across the support system to avoid point stress and deformation of the pipeline.

Best Practices for Installing Industrial-Grade Pipe Supports

Proper installation is just as important as design when it comes to ensuring thermal efficiency and the long-term stability of high-pressure pipeline systems. Following best practices during installation can prevent many common issues:

1. Correct Support Spacing

Improper spacing of pipe supports can result in excessive stress on certain sections of the pipeline, leading to deformation or failure. Its essential to ensure that supports are spaced according to the pipelines size, weight, and thermal load. The correct spacing minimizes the risk of sagging or misalignment, ensuring efficient operation over the long term.

2. Consideration of Expansion and Contraction

High-pressure pipelines often undergo thermal expansion, which should be considered during installation. Expansion loops or flexible supports should be incorporated into the design to ensure that the pipeline can expand and contract without compromising the systems integrity.

3. Use of Corrosion-Resistant Coatings

To enhance the durability of pipe supports in harsh environments, its essential to use corrosion-resistant coatings or choose materials that inherently resist corrosion. This extends the lifespan of the supports and prevents degradation in high-pressure, corrosive environments.

Conclusion: Achieving Optimal Performance with Proper Pipe Support Installation

The design and installation of pipeline insulation supports in high-pressure environments require careful consideration of materials, thermal performance, and mechanical strength. By selecting the appropriate materials and ensuring correct installation techniques, industries can significantly improve pipeline system efficiency, reduce energy loss, and extend the lifespan of their infrastructure.

To meet the challenges of high-pressure systems, industrial-grade pipe supports must be durable, thermally efficient, and resistant to the harsh conditions they will face. By adhering to design standards and installation best practices, companies can optimize their pipeline performance and avoid costly operational issues.

Closing Summary:

Industrial-grade pipe supports are vital for ensuring the long-term performance and energy efficiency of high-pressure pipeline systems. By focusing on material selection, thermal insulation, and structural integrity, industries can create efficient, reliable pipeline systems that stand the test of time. Proper installation is key to achieving these goals and ensuring the success of pipeline infrastructure in demanding environments.

References

GB/T7714:Gunnarshaug A, Metallinou M M, Log T. Study of industrial grade thermal insulation at elevated temperatures[J]. Materials, 2020, 13(20): 4613.

MLA:Gunnarshaug, Amalie, Maria Monika Metallinou, and Torgrim Log. "Study of industrial grade thermal insulation at elevated temperatures." Materials 13.20 (2020): 4613.

APA:Gunnarshaug, A., Metallinou, M. M., & Log, T. (2020). Study of industrial grade thermal insulation at elevated temperatures. Materials, 13(20), 4613.

Hot Products

Hot Products

Contact Us

Contact Us

Contact:

Mobile:+86 +86 19133378808

Website:mingdepipe.com

Address: