Pipe Insulation Bracket Guide: Key Functions, Applications, and Selection Strategies

Author:Mingde Time:2025-08-16 01:14:12 Click:125

Why the Pipe Insulation Bracket Matters

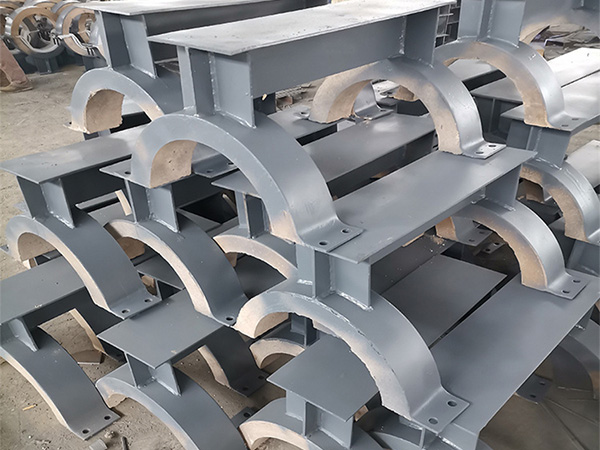

A pipe insulation bracket plays a crucial role in supporting pipelines while maintaining thermal efficiency. In both industrial and commercial applications, this component ensures that pipes remain stable, insulated, and protected against environmental or operational stresses. Whether in oil and gas, HVAC, or water supply systems, selecting the right pipe insulation bracket can directly impact system performance, longevity, and energy savings.

1. Understanding the Pipe Insulation Bracket

A pipe insulation bracket is a specially designed support component that holds insulated pipelines in place while preventing compression or damage to the insulation layer. Unlike standard pipe supports, it accommodates both the mechanical needs of pipe stability and the thermal requirements of insulation.

Key features include:

·Thermal protection to reduce heat transfer

·Mechanical support to prevent sagging or misalignment

·Durability to withstand temperature changes, vibration, and corrosion

·Compatibility with various pipe diameters and insulation thicknesses

2. Core Functions of the Pipe Insulation Bracket

The main functions of a pipe insulation bracket go beyond simple support:

Maintaining Thermal Integrity

Prevents heat loss or gain by preserving the insulation layer’s shape and performance.

Ensuring Structural Stability

Keeps pipes properly aligned, avoiding excessive stress on joints and connections.

Reducing Condensation Risks

Minimizes the possibility of condensation forming on cold pipes, which can lead to corrosion.

Supporting Heavy Loads

In high-pressure pipelines, brackets distribute weight evenly to prevent deformation.

3. Common Applications

Pipe insulation brackets are used in multiple industries where both structural and thermal needs are important.

·Industrial Pipelines – Oil, gas, and chemical facilities use them to protect pipelines from extreme temperatures and mechanical wear.

·HVAC Systems – Ensures heating and cooling lines remain insulated and stable.

·District Heating Networks – Maintains thermal efficiency over long-distance heat transport.

·Food and Beverage Processing – Helps maintain strict temperature control for hygienic production.

·Cryogenic Applications – Essential in systems transporting liquefied gases at extremely low temperatures.

4. Selection Strategies for the Right Pipe Insulation Bracket

Choosing the right pipe insulation bracket requires balancing mechanical strength, insulation compatibility, and cost-effectiveness.

Key selection factors include:

·Material Choice – Stainless steel for corrosion resistance, galvanized steel for cost-effective durability, or composite materials for lightweight applications.

·Insulation Compatibility – Ensure the bracket design accommodates insulation thickness without compression.

·Load Capacity – Match the bracket’s strength to the pipe diameter, insulation type, and operational weight.

·Environmental Conditions – Consider exposure to moisture, chemicals, or extreme temperatures.

·Installation Flexibility – Select designs that simplify installation and maintenance.

5. Installation Best Practices

Correct installation is essential for maximizing the performance of a pipe insulation bracket.

·Accurate Measurement – Match the bracket to the pipe’s outer diameter, including insulation thickness.

·Proper Spacing – Avoid excessive gaps between brackets to prevent sagging.

·Secure Fastening – Ensure brackets are tightly fixed but do not compress insulation.

·Thermal Breaks – Use brackets with thermal breaks to prevent conductive heat loss.

·Regular Inspection – Check brackets periodically for wear, corrosion, or loosening.

6. Maintenance Tips

To keep a pipe insulation bracket in optimal condition:

·Inspect annually for corrosion or structural damage.

·Replace damaged insulation to maintain thermal efficiency.

·Tighten or replace fasteners if they show signs of loosening.

·Clean surfaces to prevent buildup of dust, oil, or debris.

7. Benefits of a High-Quality Pipe Insulation Bracket

·Energy Efficiency – Reduced heat loss leads to lower energy costs.

·Extended Service Life – Protects both pipes and insulation from premature wear.

·Lower Maintenance Costs – Durable brackets require fewer replacements.

·Improved Safety – Stable pipelines reduce the risk of accidents.

Conclusion

A well-designed pipe insulation bracket is more than a simple support — it’s a critical component that ensures thermal efficiency, structural stability, and long-term pipeline reliability. By understanding its key functions, common applications, and selection criteria, you can choose the best bracket for your project needs.

Whether for industrial pipelines, HVAC systems, or specialized cryogenic applications, the right pipe insulation bracket will help you optimize performance, reduce energy costs, and extend the life of your entire piping system.

References

GB/T 7714:Porzuczek J. Comparative study on selected insulating materials for industrial piping[J]. Materials, 2024, 17(7): 1601.

MLA:Porzuczek, Jan. Comparative study on selected insulating materials for industrial piping." Materials 17.7 (2024): 1601.

APA:Porzuczek, J. (2024). Comparative study on selected insulating materials for industrial piping. Materials, 17(7), 1601.

Hot Products

Hot Products

Contact Us

Contact Us

Contact:

Mobile:+86 +86 19133378808

Website:mingdepipe.com

Address: