Applications of Insulation Brackets for Enhanced Pipeline Stability and Protection

Author:Mingde Time:2025-08-25 02:53:10 Click:91

Why the Pipe Insulation Bracket Matters

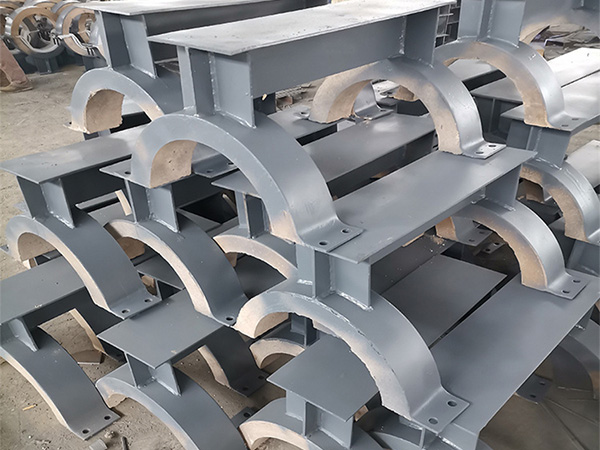

Within industrial and commercial piping setups, the Pipe Insulation Bracket serves as more than just a structural component—it is a key safeguard for both mechanical stability and thermal efficiency. Its design allows it to support pipelines under operational stress while preserving the performance of surrounding insulation, reducing energy loss, and preventing premature wear on critical infrastructure.

1. Reinforcing Structural Integrity

Pipelines in heavy-duty operations are constantly challenged by weight, vibration, and thermal expansion. The Pipe Insulation Bracket addresses these issues by:

·Distributing pipe weight evenly, preventing sagging or deformation.

·Reducing stress on welds and joints.

·Keeping pipelines properly aligned to maintain optimal flow conditions.

This reinforcement plays a vital role in lowering repair frequency and extending the overall service life of the system.

2. Preserving Thermal Performance

An often-overlooked benefit of a Pipe Insulation Bracket is its ability to maintain uninterrupted insulation coverage. By minimizing thermal bridging—the transfer of heat through metal contact points—these brackets:

·Reduce heat loss in high-temperature pipelines.

·Prevent condensation on cold-water and refrigeration lines.

·Support energy conservation efforts by stabilizing process temperatures.

3. Shielding Against Harsh Conditions

Industrial pipelines often operate in environments where moisture, chemicals, or extreme temperatures can threaten both pipes and insulation. Properly engineered insulation brackets counter these risks through:

·Corrosion-resistant materials like stainless steel or composite alloys.

·Designs that protect insulation from mechanical wear and accidental impacts.

·Durability that withstands outdoor and offshore conditions.

4. Controlling Vibration and Noise

Systems connected to pumps, compressors, or high-velocity flow lines frequently encounter vibration. A well-designed Pipe Insulation Bracket can:

·Absorb shock and reduce mechanical strain on the pipe wall.

·Limit noise transmission through structural supports.

·Improve operational safety in noise-sensitive facilities.

5. Multi-Industry Applications

The adaptability of the Pipe Insulation Bracket makes it suitable for numerous sectors:

·Oil & Gas – Withstands extreme heat, pressure, and corrosive elements.

·Food and Beverage – Maintains sanitary conditions by protecting insulation from contamination.

·Pharmaceuticals – Supports sterile pipelines with cleanable, non-porous components.

·HVAC Systems – Helps preserve temperature control in climate-sensitive installations.

6. Compatibility with Modern Engineering Practices

Contemporary insulation brackets are increasingly designed for efficiency and sustainability. They can:

·Be prefabricated for rapid on-site installation.

·Include slots for monitoring devices to track vibration or thermal changes.

·Use recyclable or low-conductivity materials to support environmental objectives.

7. Choosing the Right Insulation Bracket

When selecting a Pipe Insulation Bracket, decision-makers should review:

1.Load Support – Capability to handle both the pipe and insulation weight.

2.Material Suitability – Resistance to corrosion, chemicals, and weathering.

3.Thermal Efficiency – Ability to limit heat transfer.

4.Operational Environment – Indoor, outdoor, high-vibration, or corrosive settings.

5.Long-Term Reliability – Minimal maintenance requirements over years of use.

Conclusion: A Small Component with a Big Impact

In the complex world of piping systems, the Pipe Insulation Bracket is a compact yet essential element. It safeguards mechanical stability, optimizes thermal performance, and offers long-term protection against environmental challenges. Selecting the correct bracket design and material ensures that pipelines operate reliably, efficiently, and cost-effectively for years to come.

References

GB/T 7714:Fang J B. Calculations of maximum allowable heat losses for various shallow-trench heat-distribution systems[R]. National Bureau of Standards, Washington, DC (USA). Building Environment Div., 1987.

MLA:Fang, Jin B. Calculations of maximum allowable heat losses for various shallow-trench heat-distribution systems. No. PB-88-153721/XAB; NBSIR-87/3617. National Bureau of Standards, Washington, DC (USA). Building Environment Div., 1987.

APA:Fang, J. B. (1987). Calculations of maximum allowable heat losses for various shallow-trench heat-distribution systems (No. PB-88-153721/XAB; NBSIR-87/3617). National Bureau of Standards, Washington, DC (USA). Building Environment Div..

Hot Products

Hot Products

Contact Us

Contact Us

Contact:

Mobile:+86 +86 19133378808

Website:mingdepipe.com

Address: