Cost-Effective Pipe Insulation Bracket Selection: Balancing Performance and Budget

Author:Mingde Time:2025-08-31 20:48:10 Click:131

When planning an efficient piping system, the pipe insulation bracket is often underestimated. It not only supports the pipe’s weight but also preserves insulation integrity, minimizes heat loss, and extends the system’s operational life.

Selecting the right pipe insulation bracket means achieving reliable performance without unnecessary overspending. This guide outlines how engineers, contractors, and facility managers can strike the right balance between performance and cost.

Why Choosing the Right Pipe Insulation Bracket Matters

An unsuitable bracket can compress insulation, increase thermal loss, and cause premature wear in the system. The right pipe insulation bracket:

·Maintains insulation thickness and structural integrity at support points.

·Reduces energy waste by minimizing thermal bridging.

·Damps vibration and lowers mechanical stress on piping.

In industrial facilities, commercial buildings, and public infrastructure, informed selection is key to long-term efficiency.

Core Factors Affecting Bracket Cost-Performance Ratio

The cost of a pipe insulation bracket is more than its purchase price — its lifetime performance and maintenance demands matter just as much. Critical considerations include:

1.Load Capacity – Larger or high-pressure pipes require brackets with higher strength ratings.

2.Thermal Conductivity – Low-conductivity materials help retain insulation efficiency.

3.Corrosion Resistance – Vital in humid, marine, or chemically aggressive environments.

4.Ease of Installation – Reduces labor time and overall project costs.

Balancing these elements ensures you don’t overpay for excessive specifications or risk failures from under-engineering.

Material Choices and Long-Term Value

The bracket’s material is central to its durability and cost-effectiveness. Common options include:

·Galvanized Steel – Strong and economical, but may require coating in harsh environments.

·Stainless Steel – Higher upfront investment, but superior corrosion resistance for extended service life.

·Composite Materials – Lightweight, thermally efficient, and increasingly favored for energy-conscious projects.

While certain materials may cost more initially, energy savings and reduced maintenance often outweigh the higher purchase price.

Design Innovations That Improve Performance

Modern pipe insulation bracket designs offer features that go beyond simple support:

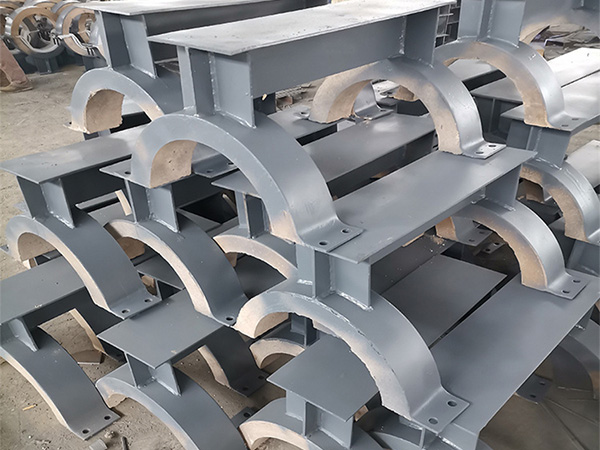

·Integrated Insulation Saddles – Maintain consistent insulation thickness even at load-bearing points.

·Adjustable Mounts – Simplify installation and accommodate thermal expansion.

·Vibration Isolation Features – Reduce stress on the piping system and extend operational lifespan.

Strategic design choices can deliver better performance without pushing costs beyond budget.

Installation and Maintenance Best Practices

Even a premium pipe insulation bracket cannot perform effectively if installed incorrectly. Recommended practices include:

·Following industry guidelines for spacing, alignment, and support type.

·Using fasteners compatible with the bracket’s material to prevent galvanic corrosion.

·Conducting regular inspections for signs of wear, insulation compression, or loosening.

A proactive approach to maintenance ensures both the brackets and the piping remain in peak condition.

Balancing Cost and Performance

Finding the right pipe insulation bracket involves life-cycle cost analysis — weighing purchase price against:

·Energy savings from reduced heat loss.

·Lower maintenance and replacement needs.

·Improved operational reliability and safety.

In many cases, investing slightly more upfront pays for itself in long-term savings.

Conclusion: A Smart Investment in Infrastructure

Selecting the right pipe insulation bracket is less about minimizing cost and more about maximizing value. Considering load requirements, thermal performance, material durability, and installation efficiency allows decision-makers to secure optimal performance without exceeding budget limits.

Ultimately, a well-chosen pipe insulation bracket strengthens the efficiency, longevity, and cost-effectiveness of the entire piping system — making it a small component with a big impact.

References

GB/T 7714:Sullivan J M. Thermal performance of insulated pipe systems[C]//Thermal Insulation, Materials, and Systems for Energy Conservation in the'80s. ASTM International, 1983: 778-795.

MLA:Sullivan, J. M. "Thermal performance of insulated pipe systems." Thermal Insulation, Materials, and Systems for Energy Conservation in the'80s. ASTM International, 1983.

APA:Sullivan, J. M. (1983, January). Thermal performance of insulated pipe systems. In Thermal Insulation, Materials, and Systems for Energy Conservation in the'80s (pp. 778-795). ASTM International.

Hot Products

Hot Products

Contact Us

Contact Us

Contact:

Mobile:+86 +86 19133378808

Website:mingdepipe.com

Address: