Custom Pipe Insulation Bracket Solutions for Special Applications

Author:Mingde Time:2025-09-07 19:04:54 Click:192

The Hidden Role of Pipe Insulation Brackets

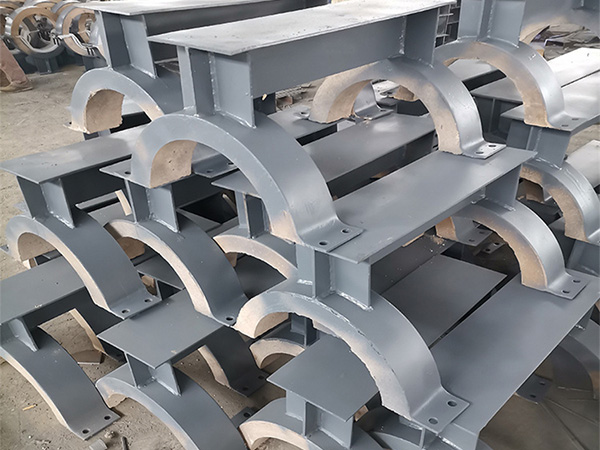

Behind every reliable piping system lies an element that often goes unnoticed: the pipe insulation bracket. While small in size, these supports ensure pipes remain stable, insulation stays effective, and energy efficiency is preserved. In special applications—such as extreme temperature facilities, chemical plants, or tight mechanical spaces—standard hardware falls short. That’s when a custom pipe insulation bracket becomes indispensable.

Why Customization Is Essential

Every piping setup faces its own operational challenges. A one-size-fits-all approach rarely works when the system operates under unusual conditions. A custom pipe insulation bracket allows engineers and contractors to address factors like:

·Thermal performance – Preventing energy loss by minimizing thermal bridging.

·Durability – Withstanding exposure to corrosive or high-moisture environments.

·Structural integrity – Carrying the weight of insulated pipes without sagging or shifting.

·Space constraints – Adapting to unique layouts where traditional supports don’t fit.

By tailoring the bracket design, the insulation remains continuous and reliable, even in the toughest settings.

Examples of Special Applications

Certain industries demand solutions that go beyond conventional pipe supports. Here are a few cases where custom pipe insulation brackets are especially valuable:

1.Power and Energy Plants

Pipes transporting steam or hot fluids need brackets that resist high heat while preserving insulation thickness.

2.Cold Chain Logistics

In freezers and refrigerated storage, brackets must reduce condensation risk and keep thermal layers intact.

3.Chemical Processing Facilities

Harsh chemicals corrode standard metals, so brackets require specialized coatings or non-corrosive materials.

4.Marine and Aerospace Systems

Limited space and vibration demand compact, lightweight designs that secure insulation without compromise.

Advantages of Custom Pipe Insulation Brackets

Opting for a tailored solution offers several benefits that standard brackets simply cannot provide:

·Consistent insulation performance – Eliminates weak points where heat or cold could escape.

·Extended equipment lifespan – Protects both piping and insulation from premature wear.

·Lower maintenance needs – Reduces risk of sagging, moisture penetration, and frequent replacements.

·Improved safety – Provides secure, stable support in critical applications.

These advantages translate directly into reduced operating costs and long-term reliability.

Key Factors in Designing Custom Solutions

Designing a pipe insulation bracket for demanding environments requires balancing multiple technical considerations:

·Material selection – Stainless steel, composites, or coated metals are chosen based on the operating environment.

·Load-bearing calculations – Brackets must support static and dynamic forces without deforming.

·Insulation continuity – Designs should prevent compression that disrupts thermal performance.

·Ease of installation – A bracket that is simple to install saves labor and reduces system downtime.

When these factors align, the result is a solution that serves its function for years with minimal intervention.

Best Practices for Installation

Even a perfectly designed pipe insulation bracket will underperform if installed incorrectly. To maximize effectiveness:

·Ensure precise alignment with pipe runs before tightening.

·Avoid excessive compression that damages insulation layers.

·Use compatible fasteners to prevent galvanic corrosion.

·Conduct routine inspections in high-stress systems.

Proper installation ensures that insulation remains undisturbed, preserving both energy efficiency and mechanical safety.

Long-Term Value of the Right Bracket

Investing in a custom-designed bracket pays dividends well beyond initial installation. By supporting insulation performance, a pipe insulation bracket reduces heat loss, prevents condensation, and minimizes unnecessary repairs. Over time, this leads to measurable energy savings, fewer shutdowns, and more sustainable operations.

For industries facing stringent environmental or efficiency standards, the right bracket solution becomes a cornerstone of compliance and long-term cost control.

Conclusion: Pipe Insulation Brackets Built for Demanding Environments

No two projects are exactly alike, and neither are the conditions they operate under. That’s why a custom pipe insulation bracket is often the only way to ensure reliability in specialized applications. Whether the challenge is extreme temperature, chemical exposure, or limited space, these brackets provide the strength, adaptability, and insulation continuity that standard supports cannot deliver.

From design to installation and ongoing performance, the right pipe insulation bracket offers more than support—it ensures energy efficiency, safety, and system stability. In every special application, choosing a tailored solution guarantees that the system performs exactly as required, from start to finish.

References

GB/T 7714:Branzoi A E. CFD and Heat Transfer Analysis of Insulated Pipe Supports with PTFE Pads in High-Temperature Environments[D]. , 2025.

MLA:Branzoi, Ana-Emilia. CFD and Heat Transfer Analysis of Insulated Pipe Supports with PTFE Pads in High-Temperature Environments. Diss. 2025.

APA:Branzoi, A. E. (2025). CFD and Heat Transfer Analysis of Insulated Pipe Supports with PTFE Pads in High-Temperature Environments (Doctoral dissertation).

Hot Products

Hot Products

Contact Us

Contact Us

Contact:

Mobile:+86 +86 19133378808

Website:mingdepipe.com

Address: