Integration of Brackets into Prefabricated Pipeline Modules

Author:Mingde Time:2026-01-15 13:37:01 Click:197

Integration of Brackets into Prefabricated Pipeline Modules

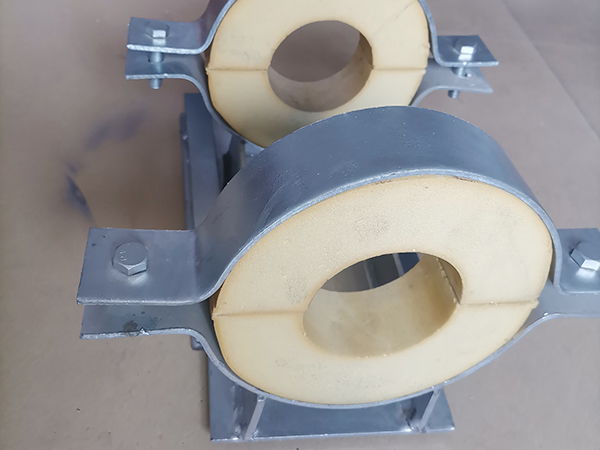

As industrial construction increasingly shifts toward modularization, prefabricated pipeline systems have become a preferred solution for improving installation efficiency and quality control. Within these systems, the Pipeline Insulation Bracket plays a critical role in ensuring structural support, thermal stability, and long-term operational reliability.

From a manufacturer and production standpoint, integrating brackets directly into prefabricated pipeline modules allows for better dimensional accuracy, reduced on-site labor, and improved consistency across large-scale projects. This article examines how brackets are integrated into prefabricated pipeline modules and why this approach is becoming a standard practice in modern pipeline engineering.

Understanding Prefabricated Pipeline Modules

Prefabricated pipeline modules are pre-assembled sections of piping systems manufactured in controlled factory environments. These modules typically include pipes, fittings, valves, insulation layers, and support components.

Unlike traditional on-site assembly, prefabrication allows production teams to standardize processes, improve quality assurance, and shorten project timelines. The integration of structural components such as brackets during production is a key advantage of this method.

Role of Pipeline Insulation Brackets in Modular Systems

Structural Support and Load Distribution

A Pipeline Insulation Bracket is designed to support pipelines while maintaining the integrity of insulation materials. In modular systems, brackets help distribute static and dynamic loads evenly across the module.

Properly integrated brackets prevent excessive stress on pipes and insulation, reducing the risk of deformation or mechanical failure during operation.

Thermal Performance Protection

Insulation brackets create controlled spacing between the pipeline and external supports. This spacing minimizes thermal bridging and helps maintain consistent insulation thickness throughout the module.

By integrating brackets during production, manufacturers can ensure precise alignment and consistent thermal performance.

Benefits of Integrating Brackets During Production

Improved Dimensional Accuracy

Factory integration allows brackets to be positioned with high precision using standardized fixtures and measurement systems. This ensures that bracket placement aligns perfectly with pipeline geometry and insulation design.

Accurate placement reduces alignment issues during installation and helps maintain system stability over time.

Reduced On-Site Installation Time

When brackets are pre-installed within pipeline modules, on-site assembly becomes significantly faster. Installers can position modules directly without adjusting or welding additional supports.

This approach reduces labor costs, minimizes installation errors, and improves overall project efficiency.

Manufacturing Considerations for Bracket Integration

Material Compatibility

During production, manufacturers must ensure that bracket materials are compatible with pipe materials and insulation systems. Corrosion resistance, thermal expansion properties, and load-bearing capacity are carefully evaluated.

Standardized material selection during production helps maintain consistent performance across all modules.

Welding and Fixation Techniques

Depending on system requirements, brackets may be welded, bolted, or mechanically fixed during module assembly. Controlled production environments allow for repeatable welding quality and thorough inspection.

Consistent fixation methods enhance long-term reliability and reduce maintenance requirements.

Quality Control in Prefabricated Bracket Integration

Inspection and Testing

Integrated brackets undergo dimensional checks, load testing, and visual inspections as part of the production process. These inspections ensure that each Pipeline Insulation Bracket meets design specifications before delivery.

Factory-based testing is more reliable than on-site inspection, where conditions may vary.

Standardization Across Bulk Production

For large projects requiring multiple pipeline modules, standardization is essential. Bulk production enables manufacturers to apply identical bracket designs and installation methods across all units.

This consistency improves interchangeability and simplifies maintenance planning.

Design Flexibility and Customization

Although standardization is important, prefabricated pipeline systems also require flexibility. Manufacturers can adjust bracket spacing, load capacity, and insulation clearance to meet specific project needs.

A production-focused approach allows customization without sacrificing efficiency, particularly when supported by modular design principles.

Installation and Operational Advantages

Enhanced Safety

Pre-integrated brackets reduce the need for extensive on-site fabrication, which lowers safety risks associated with welding and working at height.

Modules arrive ready for installation, allowing crews to focus on positioning and connection rather than structural assembly.

Long-Term System Reliability

Brackets installed under controlled production conditions are less prone to installation errors. This contributes to improved system durability, reduced vibration issues, and better insulation performance over time.

Importance of Production Capability in Bulk Supply

The success of bracket integration depends heavily on manufacturing capability. Suppliers with advanced production facilities can maintain tight tolerances, consistent welding quality, and reliable inspection processes.

Bulk supply of prefabricated modules with integrated brackets requires scalable production capacity and stable quality management systems.

Conclusion

The integration of brackets into prefabricated pipeline modules represents a significant advancement in modern pipeline construction. By incorporating the Pipeline Insulation Bracket directly during manufacturing, projects benefit from improved dimensional accuracy, faster installation, and enhanced long-term reliability.

From a manufacturer-led production and bulk supply perspective, this approach ensures consistent quality and predictable performance across large-scale pipeline systems. As modular construction continues to expand, integrated bracket solutions will remain a key element in efficient and reliable pipeline design.

References

GB/T 7714:Grossel S S. Valve Selection Handbook[J]. Chemical Engineering, 2004, 111(12): 10-11.

MLA:Grossel, Stanley S. "Valve Selection Handbook." Chemical Engineering 111.12 (2004): 10-11.

APA:Grossel, S. S. (2004). Valve Selection Handbook. Chemical Engineering, 111(12), 10-11.

Hot Products

Hot Products

Contact Us

Contact Us

Contact:

Mobile:+86 +86 19133378808

Website:mingdepipe.com

Address: