Thermal Stress Management with Advanced Pipe Insulation Brackets

Author:Mingde Time:2025-11-21 19:46:59 Click:196

Industrial pipelines are constantly exposed to temperature extremes—whether transporting hot steam, thermal oil, cryogenic liquids, or chemically reactive media. These dramatic temperature fluctuations cause thermal expansion and contraction, which can place immense stress on the piping system if not properly managed. To maintain structural safety and ensure system longevity, facilities rely heavily on advanced Pipeline Insulation Bracket solutions engineered specifically to handle thermal stress.

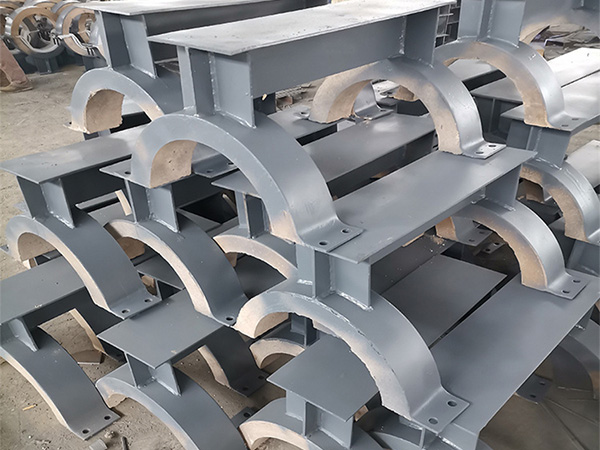

Modern insulation brackets serve as a crucial interface between insulated pipes and their support structures. They maintain insulation integrity, minimize heat transfer, and allow controlled pipe movement under thermal cycles. When sourced from a qualified manufacturer with consistent production capabilities, these brackets deliver reliable performance even in large-scale industrial settings.

Understanding the Impact of Thermal Stress in Piping Systems

Thermal stress occurs when pipe materials expand or contract in response to temperature changes. Without appropriate support:

·Pipes may warp or shift

·Anchor loads increase beyond safe limits

·Joints and welds experience greater strain

·Vibration becomes more pronounced

·Structural misalignment can occur

These factors ultimately compromise system stability. Pipeline insulation brackets are specifically engineered to mitigate these effects by holding the pipe securely while isolating the surrounding structure from extreme temperatures.

Why a Pipeline Insulation Bracket Is Critical to System Performance

A Pipeline Insulation Bracket serves multiple roles beyond simply securing a pipe. It balances structural support, thermal isolation, and insulation preservation to ensure stable operation across temperature fluctuations. Key contributions include:

·Maintaining insulation thickness and preventing compression

·Reducing energy loss by avoiding thermal bridging

·Supporting pipeline weight without damaging insulation layers

·Allowing expansion without overstressing anchors

·Protecting structural steel from heat exposure

By integrating these functions, insulation brackets significantly improve the durability and efficiency of industrial pipeline networks.

Advantages of Advanced Pipeline Insulation Bracket Technology

1. Superior Thermal Efficiency and Energy Retention

When insulation is compressed, thermal resistance drops dramatically. High-quality insulation brackets ensure insulation remains intact and uniform, providing:

·Better heat retention for hot pipelines

·Improved cooling performance for cold or cryogenic systems

·Reduced energy consumption

·Increased insulation lifespan

This directly contributes to lower operational costs and improved system performance.

2. Effective Reduction of Thermal Expansion Forces

As temperature rises, pipelines lengthen. Advanced brackets are engineered to accommodate controlled movement while maintaining alignment. This prevents:

·Support system overloading

·Pipe deformation

·Stress at welded joints and flanges

·Failures caused by rigid anchoring

Properly designed brackets relieve stress and protect the piping over long-term operation.

3. Increased Structural Protection Through Heat Isolation

Heat transferred from pipelines into building structures can create long-term degradation. Insulation brackets incorporate thermal-break materials to:

·Reduce heat flow into beams and platforms

·Minimize thermal fatigue

·Prevent material weakening over time

·Support compliance with safety standards

This isolation is essential in high-temperature environments such as refineries, power plants, and processing facilities.

4. Improved Resistance to Vibration and Mechanical Shock

Pipes connected to pumps, valves, and rotating machines experience vibration that can loosen fasteners or damage insulation. Advanced insulation brackets often include:

·Shock-absorbing inserts

·Anti-vibration pads

·Reinforced mounting plates

·Noise-reducing linings

These features protect both the pipe and surrounding equipment.

5. Material Options Tailored for Demanding Environments

Pipeline insulation brackets can be built with a wide range of materials, depending on the thermal, chemical, and structural conditions, including:

·Stainless steel for corrosion-prone environments

·Galvanized steel for general industrial use

·Composite materials to limit thermal transfer

·Heat-resistant or fire-safe insulating components

This allows them to function reliably in chemical plants, offshore platforms, chilled-water systems, and more.

Industries That Rely on Insulated Pipe Support Systems

Pipeline insulation brackets play a vital role across multiple sectors:

·Oil and gas

·Chemical and petrochemical

·Power generation

·HVAC and refrigeration

·Pharmaceutical and food manufacturing

·Water treatment and distribution

·Marine and offshore engineering

Any industry managing temperature-sensitive media benefits from these specialized support systems.

What to Consider When Selecting a Pipeline Insulation Bracket

1. Temperature Range and Insulation Requirements

Each bracket must match the operational temperature and insulation type.

2. Structural Load and Pipe Weight

Correct load rating prevents sagging, misalignment, and fatigue.

3. Environmental and Chemical Exposure

Material choice is influenced by humidity, corrosion potential, and atmospheric conditions.

4. Thermal Expansion Behavior

Brackets should allow controlled movement to minimize stress.

5. Manufacturer Expertise and Production Reliability

A dedicated pipeline bracket manufacturer ensures precise design, consistent production, and reliable supply for bulk orders.

Why Work with a Professional Insulated Pipe Support Manufacturer?

Partnering with a specialized manufacturer ensures:

·Custom engineering for unique project conditions

·Quality assurance through controlled production processes

·Bulk availability with consistent dimensional accuracy

·Technical support for thermal and structural calculations

·Long-term reliability backed by robust materials

This guarantees stable performance throughout the entire life cycle of the pipeline system.

Conclusion: Advanced Insulation Brackets Are Key to Thermal Stress Control

Managing thermal stress is essential for the safety and efficiency of industrial pipeline systems. Advanced Pipeline Insulation Bracket solutions provide the thermal isolation, movement accommodation, and long-term structural protection required in temperature-intensive environments. They reduce system fatigue, maintain insulation integrity, and support reliable operation.

Working with an experienced Pipeline Insulation Bracket manufacturer ensures that each component is engineered for durability and produced with consistent quality. With dependable support and stable production capacity, these advanced insulation brackets help industrial facilities operate safely, efficiently, and with confidence.

A high-performance system begins with a properly engineered support—starting with the right Pipeline Insulation Bracket.

References

GB/T 7714:Blevins R D. Formulas for dynamics, acoustics and vibration[M]. John Wiley & Sons, 2015.

MLA:Blevins, Robert D. Formulas for dynamics, acoustics and vibration. John Wiley & Sons, 2015.

APA:Blevins, R. D. (2015). Formulas for dynamics, acoustics and vibration. John Wiley & Sons.

Hot Products

Hot Products

Contact Us

Contact Us

Contact:

Mobile:+86 +86 19133378808

Website:mingdepipe.com

Address: